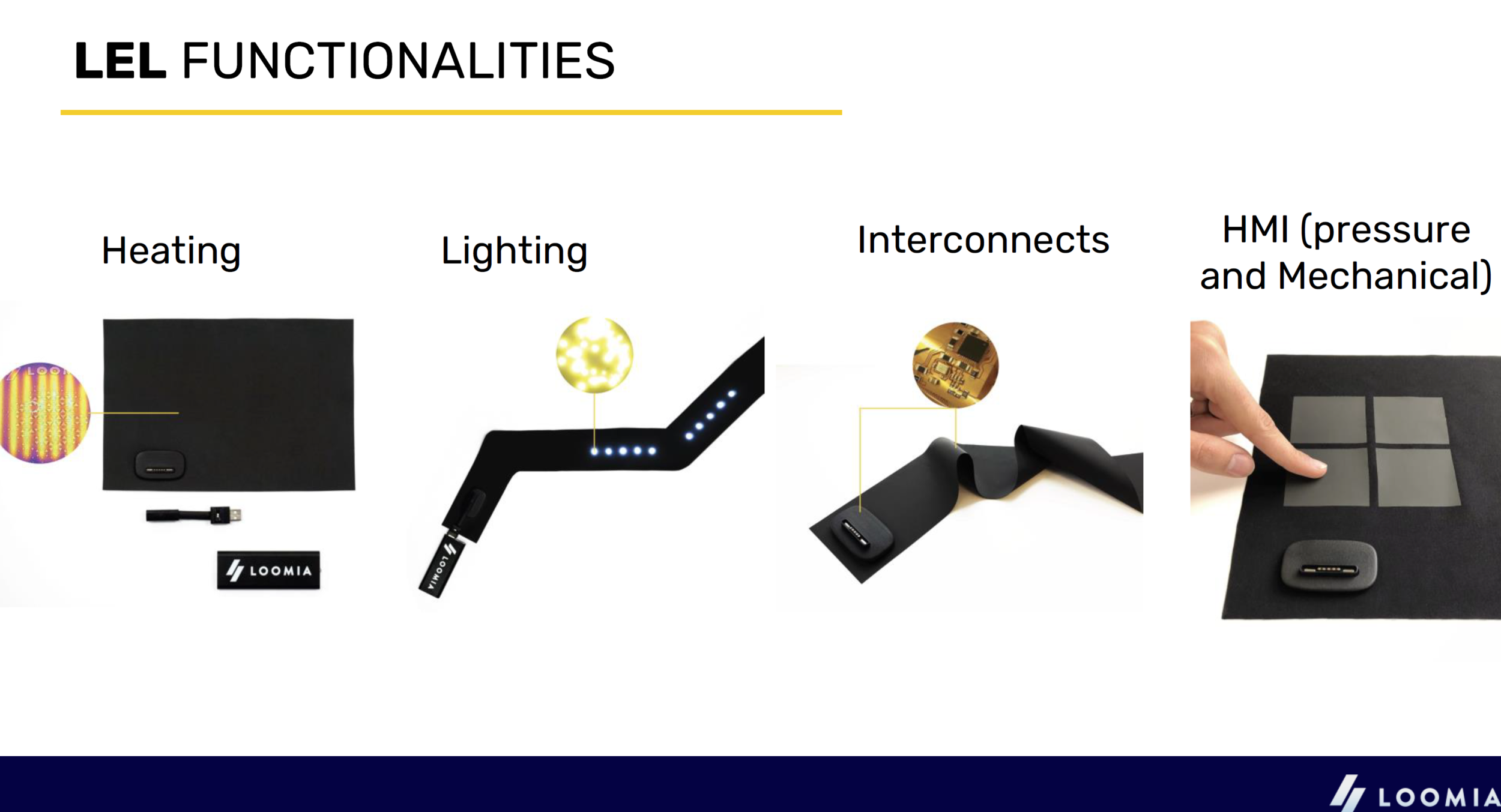

A Deep Dive into the LEL Capabilities

We’ve covered a lot of territory on the blog thus far: what e-textiles/smart textiles are, how they work, what they can be used for, and how they compare to the alternatives. A topic we haven’t gone into detail about, however, is our technology; the LEL (LOOMIA Electronic Layer, in case you forgot what that stands for). We also haven’t made the case for how we stand out from the crowd. While we belong to a very small and niche market, comparable solutions to ours are being released as more companies realize that a golden opportunity lies at the intersection of textiles and technology.

Heating

The LEL heating system consists of a fully insulted heating panel that is thin, flexible, and can be easily integrated into any textile product. With adjustable heat and temperature dispersion, it is the perfect solution for any product that requires efficient heating. Here are the main technical specifications of our heating system:

LEL Heating vs. Others

The LEL has a custom range of 3v-12v, or standard of 5v (for reference, a heated glove would take approx. 3.7v and a car seat would take approx. 12v to produce adequate heat). Most comparable textile-based heating systems can take 12v, but do not put out as much heat) and in as wide of a surface area) as the LEL.

The LEL system can heat up to 200 degrees Fahrenheit (93 degrees Celsius). A similar product on the market today (with the same surface area) can only heat to around 160 degrees Fahrenheit.

Can pass CC certification (does not interfere with other communication signals)

Can heat with as little as 1A

As for the specific applications this solution can be applied to, the list is virtually endless. Among the most exciting, however is automotive heating for steering wheels and car seats. A little while back, LOOMIA designed a custom heater for a large Original Equipment Manufacturer (OEM). This heater was made to be used in car seats and was designed to adhere directly to the leather of the seat. It was found that the LEL system produced a higher temperature threshold with less current pull than a hard wire heater – the standard method used. It was also found that the LEL produced more even heating, and at a faster time to max temperature.

Earlier this year, we conducted in-house tests on the LEL’s potential to reduce the efficacy of bacteria. The aim of this experiment was to understand how LEL heating under a textile could have an impact on bacteria that may be on the surface of a textile. According to the World Health Organization, temperatures of 132 degrees Fahrenheit or more are known to kill certain viruses and bacteria, such as SARS Coronavirus. With this in mind, we wondered if the LEL, which can heat up to 200 degrees Fahrenheit, could also be anti-bacterial or anti-viral. Turns out; it might be. When bacteria were heated on the surface of the LEL, there was a 50 percent reduction after just two minutes of heating! This needs more exploration to be scientifically proven, but just imagine if this could be applied to PPE.

Sensing/Interconnects

The LEL soft circuit system can be designed to output visual and tactile responses to sensor readings and can integrate any SMD (Surface-Mount Device) into a product. This allows for input/output mechanisms to be used in LEL-powered soft circuit systems. Most comparable solutions contain hard-to-integrate wires. LOOMIA’s soft circuits contain flat wires, so it can be more easily bonded or sewn into a product and easily customized due to its infinite bend radius. Here are some additional advantages to our soft circuit system:

No bend radius limitation. Most products on the market have a bend radius of up to 5mm.

.01ohm/square

Tensile strength of 5lbf with no resistance change, and up to 20lbf with an acceptable resistance change

Up to 20 percent stretch possible, through a serpentine design

Our customers have found the LOOMIA interconnect system to be robust, comfortable, and reliable with strong signal integrity that can support SPI or I2C connections.

When it comes to systems that combine our interconnect and sensor integration methods, wearables are not the only application. Our smart textiles can also be used to make a driving or flying experience more enjoyable via smart user interfaces and embedded technology. Just last year, TAP Air Portugal installed passenger seating equipped with sensors that would collect data on passenger behavior during flight. The information collected can help the airline make better decisions for the comfort of passengers and is a promising first step towards a new generation of air travel. LOOMIA’s soft circuit system would be ideal for this application, as it could be embedded right into the seat upholstery. As opposed to the current system which requires the bottom cushion to be removed for access.

HMI/Lighting

The LEL System can combine lights and flat, flexible switches for modern looking HMI. For automotive interiors and consumer electronics, our mechanical and pressure buttons can remove component bulk; adhering right to a surface fabric. Some additional specs include:

Adjustable light animation, color, and placement options

Custom, low-axis height boards for LEDs

Luminous flux of 300 to 400 lm/ft, and a luminous efficacy of 25 to 30 lm/W

Mechanical buttons tested for 10,000 presses up to 5lbf

Our lighting and user interface systems can be used for a wide range of purposes; from a single button on a wearable device, to a full set of controls on a dashboard. Our lighting can also be used for purely aesthetic purposes – just imagine the LEL illuminating the roof of a car like a Starlight Headliner.

Curious and want to know how our technology can fit your use case? Purchase a sample or drop us a line with any questions!