All About Loomia’s Force Sensitive Resistor (FSR) for Flexible Pressure Sensing

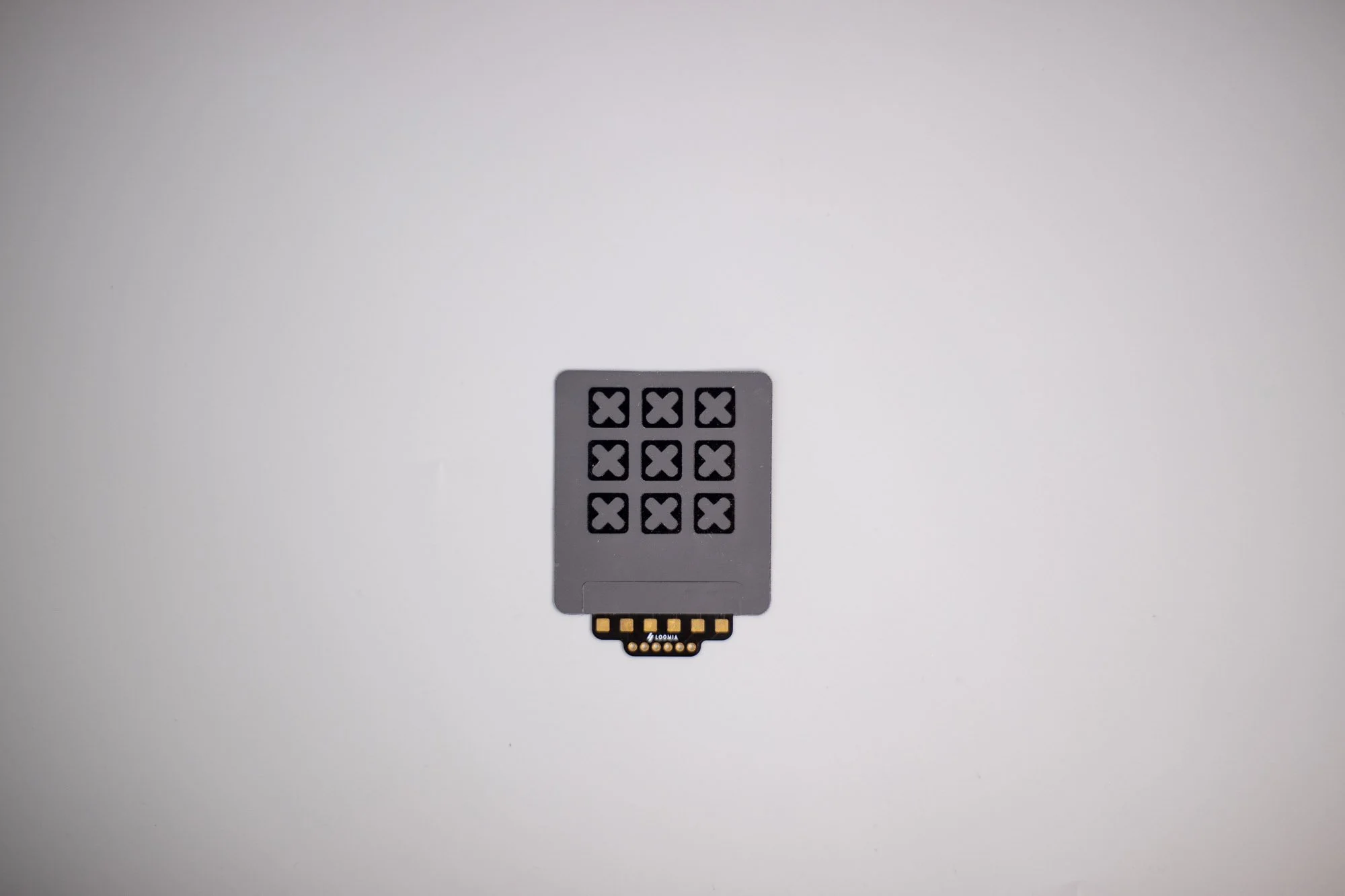

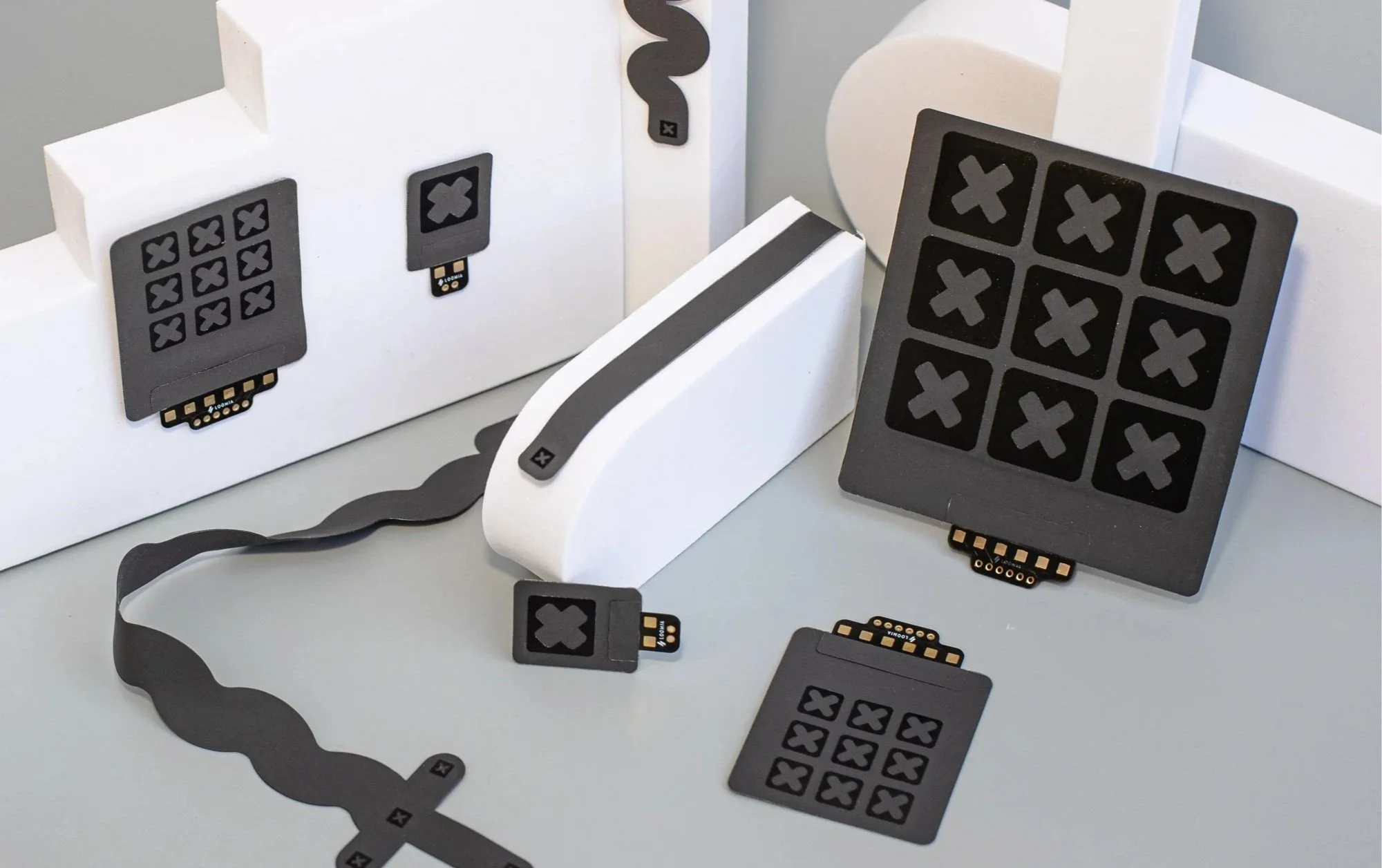

Loomia’s Force Sensitive Resistors (FSR) are thin, flexible force sensors designed for pressure sensing on curved and soft surfaces.

As force is applied to the sensors, their resistance decreases, which produces a continuous analog signal that maps applied force in real time.

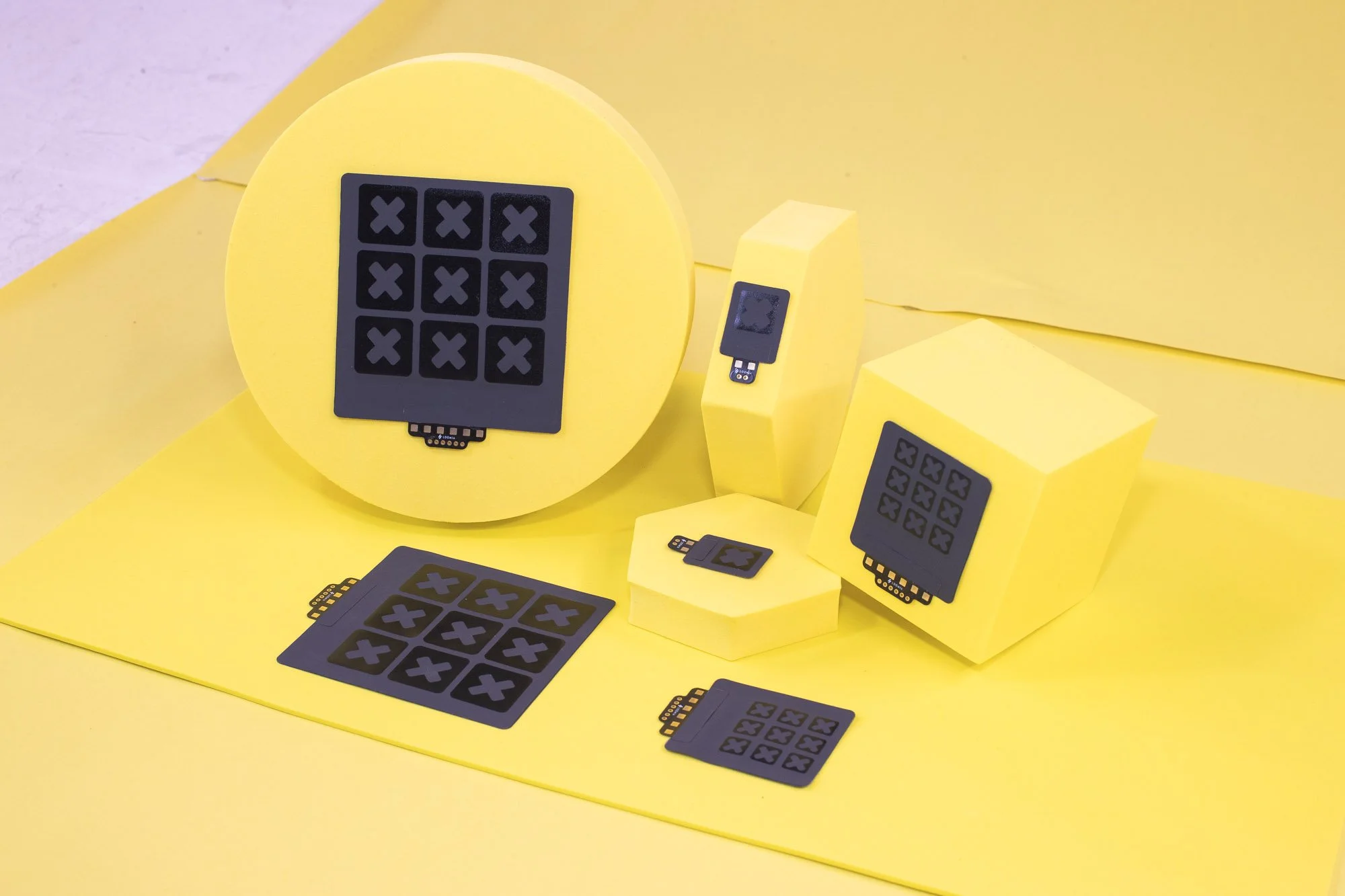

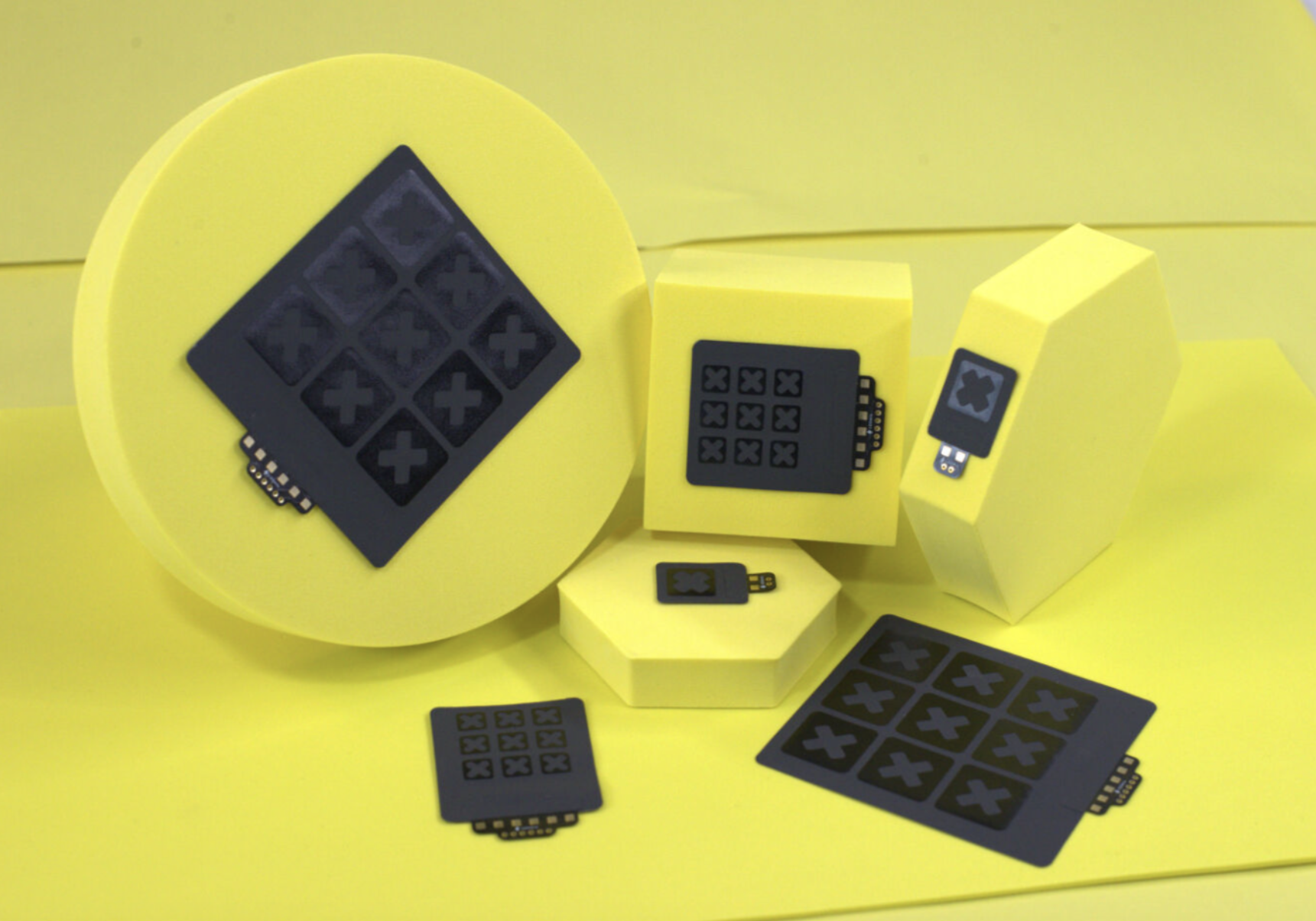

Loomia’s sensing solutions include Single FSR, Mini Pressure Matrix, and Mega Pressure Matrix options.

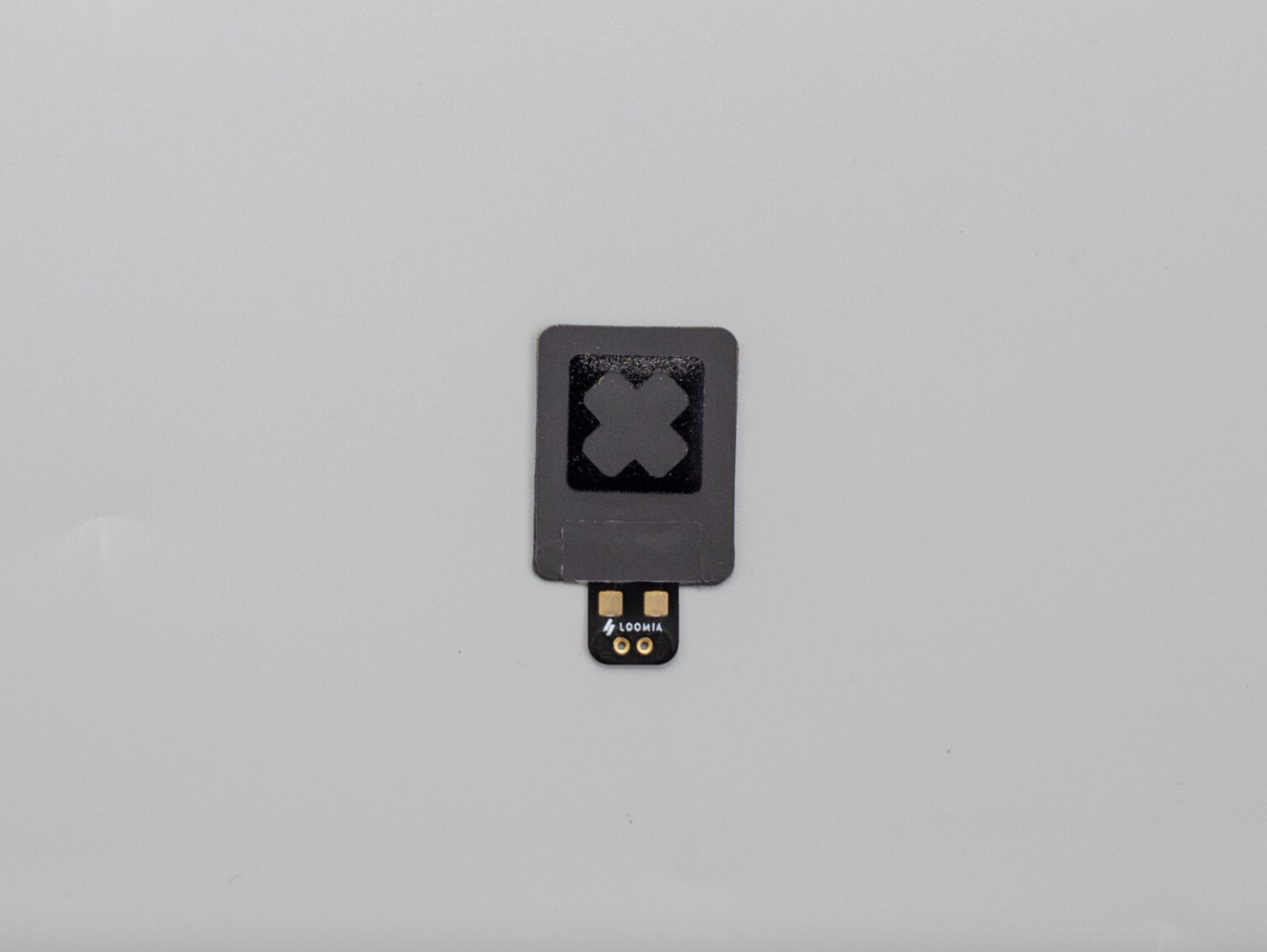

Single Flexible FSR: point-based force sensing with analog output, ideal for compact pressure detection.

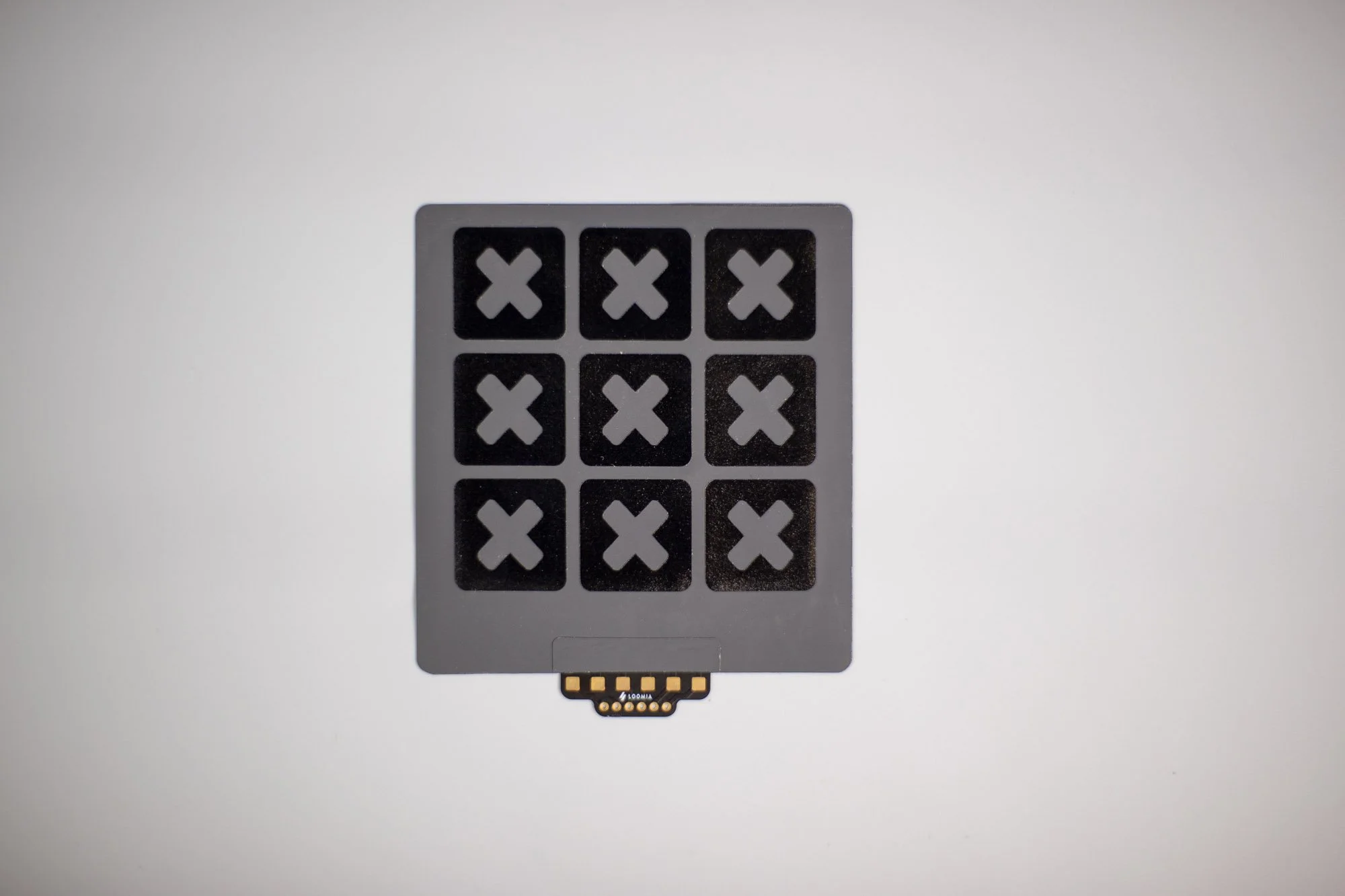

The Mini Matrix FSR: small area pressure mapping with multiple sensing points.

The Mega Matrix FSR: large-area pressure-distribution sensing for surfaces such as seats or panels.

Loomia Force Sensitive Resistors Provide:

Robust construction suitable for curved and soft surfaces

Analog force output for proportional pressure sensing

Peel-and-stick integration for fast prototyping and production use

Easy electrical integration with pressure sensing assemblies (PSAs

Customization options for size, shape, electrode layout, and substrate

Loomia sensors support innovation in robotics applications such as grippers and end-effectors, as well as in automotive interior surfaces. To learn more, contact an engineer.

Custom FSRs

We understand that for certain applications, an off-the-shelf component is simply not compatible. Our patented Loomia Electronic Layers (LEL) can also be customized to suit a variety of needs. Fill out the form to connect with our team and discuss your needs.

-

Evaluation

1) Assess our force-sensitive resistor technology with a sample.

-

Loomia Lab

2) We’ll create your custom LEL design with you through our lab.

-

Production

3) Produce your LEL at upto 20,000 units a week

Loomia FSRs’ Test Results from an Independent University Lab

Loomia Force Sensitive Resistors have been laboratory tested across Single FSR, Mini Matrix FSR, and Mega Matrix FSR configurations to evaluate performance under real-world conditions. Testing focused on force range, repeatability, drift, durability, and mechanical robustness.

-

Loomia FSRs detect low applied forces while supporting higher force ranges suitable for practical use. Although sensors can physically withstand forces above 100N, testing shows optimal performance and recovery within a controlled operating range of approximately .5-50 N.

-

Hysteresis testing at low and high operating forces shows stable and repeatable sensor response across multiple loading cycles. At higher force levels, hysteresis is reduced, supporting consistent force measurement during repeated interactions.

-

Drift testing over extended periods indicates low and predictable drift at typical operating forces, with higher variability at very low loads. This is consistent with expected FSR behavior.

-

Mini and Mega Pressure Matrix sensors were cycled up to 10,000 times at low and high force levels. Results demonstrate sustained performance under repeated loading, supporting applications involving continuous touch or contact.

-

Bend radius testing confirms that Loomia FSRs remain functional when integrated onto curved surfaces, enabling use in soft goods, robotics interfaces, and automotive interior applications.

| Category | Test Name | Description |

|---|---|---|

| Min/Max Force | Min Force Detectable | < 0.5N |

| Max Force Detectable | 50N | |

| Breaking Force | Sensor Breaking Point | 100N |

| Hysteresis | 1N Hysteresis | Avg 5% per cycle (10 cycles at 1 N) |

| 80% Max Force Hysteresis | Avg 1% per cycle (10 cycles at 50 N) | |

| Drift | 1N Drift | 0.9% over 1 hour at 1 N |

| 80% Max Force Drift | 113.3% over 1 hour at 50 N | |

| Durability | 1N Durability | 1,000,000 cycles |

| 80% Max Force Durability | 10,000 cycles at 50N | |

| Bend Radius | Max Bend Radius Allowed | 8mm |