What Are Pressure Sensors?

Definition of pressure sensor

A pressure sensor is a device that consists of pressure sensitive elements that convert applied pressure into an output signal.

How pressure sensors work

How a pressure sensor works is dependent on the type of pressure sensor you’re using. However, there is one universal trait to all pressure sensors: they all require an applied force, and the amount of force applied determines the output. The force that is applied (be it human or mechanical) often changes the resistance of the sensor, which, when wired up to a microcontroller, can be read as an electrical output.

Types of pressure sensors

There are several different types of pressure sensors, but among the most common are Piezoresistive pressure sensors and Capacitive pressure sensors. Here’s a rundown of each:

Resistive pressure sensors

Piezoresistive pressure sensors, more commonly known as “resistive pressure sensors” or “resistors”, measure pressure according to the electrical resistance of a given material when stretched. These sensors typically exhibit a decrease in resistance when there is an increase in the amount of force applied. As far as applications go, resistive pressure sensors can be used in everything from automotive user interfaces to biomedical devices.

There are three main types of Resistive pressure sensors, and they are as follows:

Diaphragm - Best for low pressure measurement

Cylinder - Best for high pressure measurement

Combined - A mixture of both diaphragm and cylinder resistive pressure sensors

Resistive pressure sensors can also be made of one of three different materials: metal, ceramic, and silicone. Each type offers various benefits and drawbacks in relation to performance and durability.

2. Capacitive pressure sensors

Capacitive pressure sensors measure changes in the electrical capacitance that occurs as a result of diaphragm movement. The main benefit to a Capacitive sensor is its threshold for short-term, high pressure conditions. How does this sensor measure up with a Resistive pressure sensor, though? What’s its advantage? Well, its primary advantage over a Resistive sensor is its ability to operate over a wide (and increasing) temperature range; something that resistors tend to have difficulty with. Capacitive pressure sensors are commonly chosen for wireless devices, since they possess an alternating current (AC).

Capacitive pressure sensors can be made of plastic, glass, silicon, or ceramic, and each material offers a set of features to best suit specific applications. For example, silicon capacitive pressure sensors are typically best suited for medical applications.

Application areas

The global pressure sensor market is slated to gross $11.4 billion within the next three years. This comes as no surprise, seeing as pressure sensors can be used in several application areas across a wide range of industries including medical, automotive, and consumer goods.

1. Medical

There are several uses for pressure sensors in medical applications. Two of the main uses are in drug and fluid infusion and vital signs monitoring. In non-invasive cardiac monitors, for example, Micro-electromechanical System (MEMS) capacitive pressure sensors are typically used. These monitors are usually wireless, and the MEMS pressure sensors have a low power consumption so they can work easier with remote, external devices.

2. Automotive

The two main uses for pressure sensors in the automotive space are in user interfaces (dashboards, consoles, etc.) and for airbag activation. In airbags, piezoresistive pressure sensors are used to help improve reaction time and detect accident-induced compression early on. This allows for the airbag to be deployed in a manner that provides optimal protection to the driver and passengers.

3. Consumer Goods

In consumer goods, the most popular application for pressure sensors is in wearables. Whether it's in a smart device or monitor, pressure sensors can provide these products with great haptics and functionality. Take for example a smart watch; these wearables typically consist of capacitive sensors that not only lower power consumption (like in medical devices), but also help with movement detection.

Pressure sensors for prototyping

Pressure sensors used in electronics prototyping are a bit scaled down compared to those used in large industrial applications. Many of the flexible pressure sensors out there on the market through distributors like Sparkfun and Adafruit are meant for smaller surface areas can conform easily. However, this does not mean they are not strong; some can withstand up to 25 pounds of pressure!

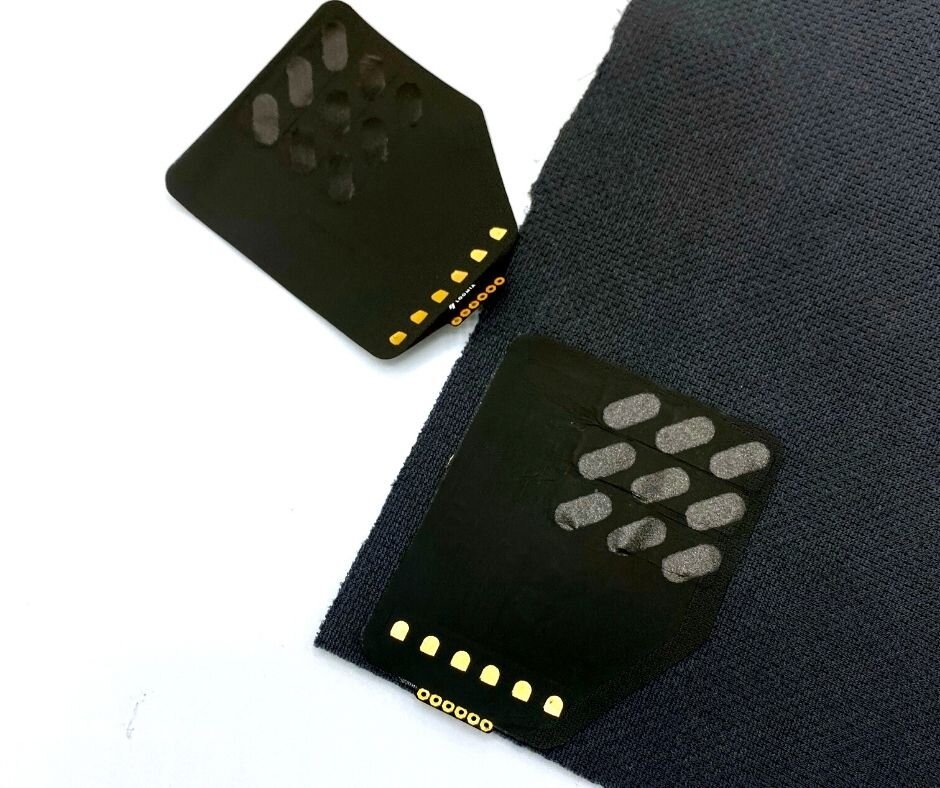

Loomia Pressure Sensor Parts

We have created a whole new line of parts to prototype with, three of which are pressure sensors! Each offer a different set of benefits and features and are best for specific applications. Our Parts have zero bend radius limitation, so they can flex and bend to meet your prototyping needs.

Single Pressure Sensor

The Single Pressure Sensor gives you an analog read that maps to force on the sensor. The more you press, the lower the resistance goes. This sensor is perfect for on-body pressure related sensing like ribcage expansion for breathing and is convenient for small surface area applications. The Single Pressure Sensor can withstand up to 10 pounds of force and pulls between 3.7V and 5V.

Learn how to setup the Single Pressure Sensor here.

2. Mega Pressure Matrix

The Mega Pressure Matrix has six leads, allowing you to map which point you are at in the 3x3 matrix and get a pressure mapping over a surface. Each area has an analog readout that varies depending on the weight of the item on the pressure sensor. Like the Single Pressure Sensor, the Mega Pressure Matrix pulls between 3.7V and 5V and can withstand up to 10 pounds of pressure. The main difference between the Mega and the Single is that the Mega has a larger dimension, so it can be used for larger surface area applications.

View the Pressure Matrix Quick-Start Guide here.

Our former Creative Tech Resident Elaine Khuu made a warming band using our Mega Pressure Matrix! This pressure-sensitive band was made with women in mind. It warms up as you rest your hand on it and cools down with firmer pressure. Check out the tutorial over on Instructables.

3. Mini Pressure Matrix

It’s the Mega Pressure Matrix’s younger sibling! The Mini Pressure Matrix has six leads, allowing you to map which point you are at in the 3x3 matrix. Each area has an analog readout that varies depending on the weight of the item on the pressure sensor. This pressure sensor possesses the same benefits of the Mega but has a smaller component dimension and sensing area dimension.

Elaine also made an adorable Stress Cat with our Mini Pressure Matrix. This is the perfect plush item for when you’re feeling fidgety or on edge while working from home. Give it a press, and it will purr! The tutorial for this adorable doodad is also available on Instructables, check it out here.