What Are Flexible Heaters? A Technology Deep Dive

A flexible heater, or flex heater, is a device which can generate heat electrically or chemically with flexible mechanical properties. Flexible heaters are bendable (to an extent) and can adhere to a variety of surfaces; be it curved or linear. They can be made using Flex PCBs, printed electronics, wires, and more. Each of these methods meet a specific set of standards for heating and overall performance, as well as size, shape, and weight requirements. So, it is crucial that the right type of flexible heater is chosen for a given application.

Types of flexible heaters

There are three common types of flexible heating elements on the market today: Polyimide flexible heaters, silicone flexible heaters, and wired heaters. Each offers a range of benefits to a manufacturer or end user, and while they are similar in many ways; they do have some unique differences. The main differences being the materiality and construction.

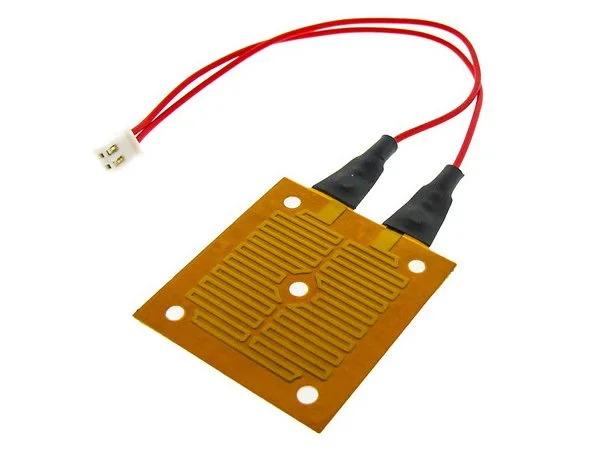

Polyimide flexible heaters

Image: Epec Engineered Technologies

Polyimide flex heaters are a great option for when you need to heat a rigid or curved surface area. They have a slim form factor and offer great tensile strength and resilience. As far as materiality goes, polyimide flex heaters consist of an etched circuit placed between two piece of polyimide film. In the chart below, you can see how they measure up with the other two types of flexible heaters we will discuss.

Silicone flexible heaters

Image: Tempco

The main benefit to silicone flexible heaters is their chemical resistance. How it works is a circuit is attached to the power leads, and then vulcanized between two layers of silicone rubber. The benefit to using silicone is that silicone is scratch resistant and repels most chemicals, making them popular for scientific applications. However, silicone heaters can also be thick, and do not always have a great electrical efficiency.

Wire heaters

Wire heaters are what you would find in a heated jacket or heated blanket. They are composed of wires that are sewn into a textile or can be made of carbon fiber in some cases. These systems can be cumbersome to install, though, but are very inexpensive to produce. The one benefit to these wire heaters, though, is they are typically enclosed in a waterproof membrane. So, they are ideal in wet conditions.

Application areas

There uses for flexible heaters are wide ranging and transcend industries. They are very versatile and can be an effective and affordable solution for heated products, provided the correct one is chosen for a given use.

Polyimide flexible heaters

There are several potential uses for polyimide flexible heaters, or “Kapton” heaters. Since they have such strong heat transfer capabilities, they are perfect in applications that require temperature regulation. Typically, polyimide flex heaters are used in aerospace, military, food service, and medical applications.

Here are some examples of products that utilize Kapton heaters:

LCD screens - Kapton heaters allow for these screens to be used in low-temperature and high moisture environments

3D printers - In 3D printers, Kapton heaters are used in the bed to keep the filament warm and improve print quality

Medical diagnostic equipment - Flexible heaters provide a strong resistance to radiation, chemicals, and bacteria

Silicone flexible heaters

Silicone flex heaters are best for large, flat surface areas. This makes them great for industrial use. For example, in heated presses, incubators, and battery heating systems. As for specific industries, they are commonly used in medical, aeronautical, military, and food service.

Examples of industrial and medical products that utilize silicone heaters:

Control panels - Silicone heaters prevent the freezing of electronics inside user interfaces

Incubators - Silicone heaters are used in incubators to ensure even and consistent heating, as well as temperature control for infants

Aerospace battery heaters - In aerospace batteries, these heaters prevent cold temperatures from effecting battery performance

Wire heaters

Many of the applications for wire heaters are focused on consumer goods. Just a few of the application areas for wire heaters include, but are not limited to: Heated blankets, heated gloves, and heated jackets.

Pros and cons of flexible heaters

There are a few benefits, and downsides, to using flexible heating elements.

The pros

Can be easily bonded to any surface

Possess a strong thermal stability across a wide temperature range

Thin and flexible form factor

Moisture and chemical resistant

Cost effective

The cons

Silicone and polyimide flex heaters, specifically, can have bend limitations, temperature and material restrictions, and environmental limitations.

Can be expensive

Can create a hazard if suddenly folded or pinched

LEL heaters

There are some clear differences between the LEL (Loomia Electronic Layer) and other flexible heaters. The LEL is thinner than silicone heaters and more flexible than polyimide heaters, making it best for integration into soft surfaces (like car seats) or heavily curved surfaces (like a round-bottom flask). The LEL heater can also be placed directly under leather or A-surface material without ghosting, which can be hard to achieve with a wire heater. Overall, LEL heaters are perfect for applications where you need high-efficiency heating close to a surface that needs to conform to a textile or unusual surface. You can check our flexible heater page for further information!

Want to learn more about how the LEL compares to other technology? Check out our Resources page for a comparative analysis, datasheets, and more.