HOW TO EVALUATE LOOMIA FORCE SENSITIVE RESISTORS (FSRs)

Reliable testing methods for accurate pressure sensor evaluation.

Learn how to test Loomia force-sensitive resistors using Arduino setups, laboratory equipment, and controlled testing techniques for consistent results.

Depending on the equipment in your lab, we present three methods for evaluation:

Static weight testing with Arduino

Lab testing with an Instron or similar equipment

Bonus note: Why static weight testing with a multimeter can be misleading

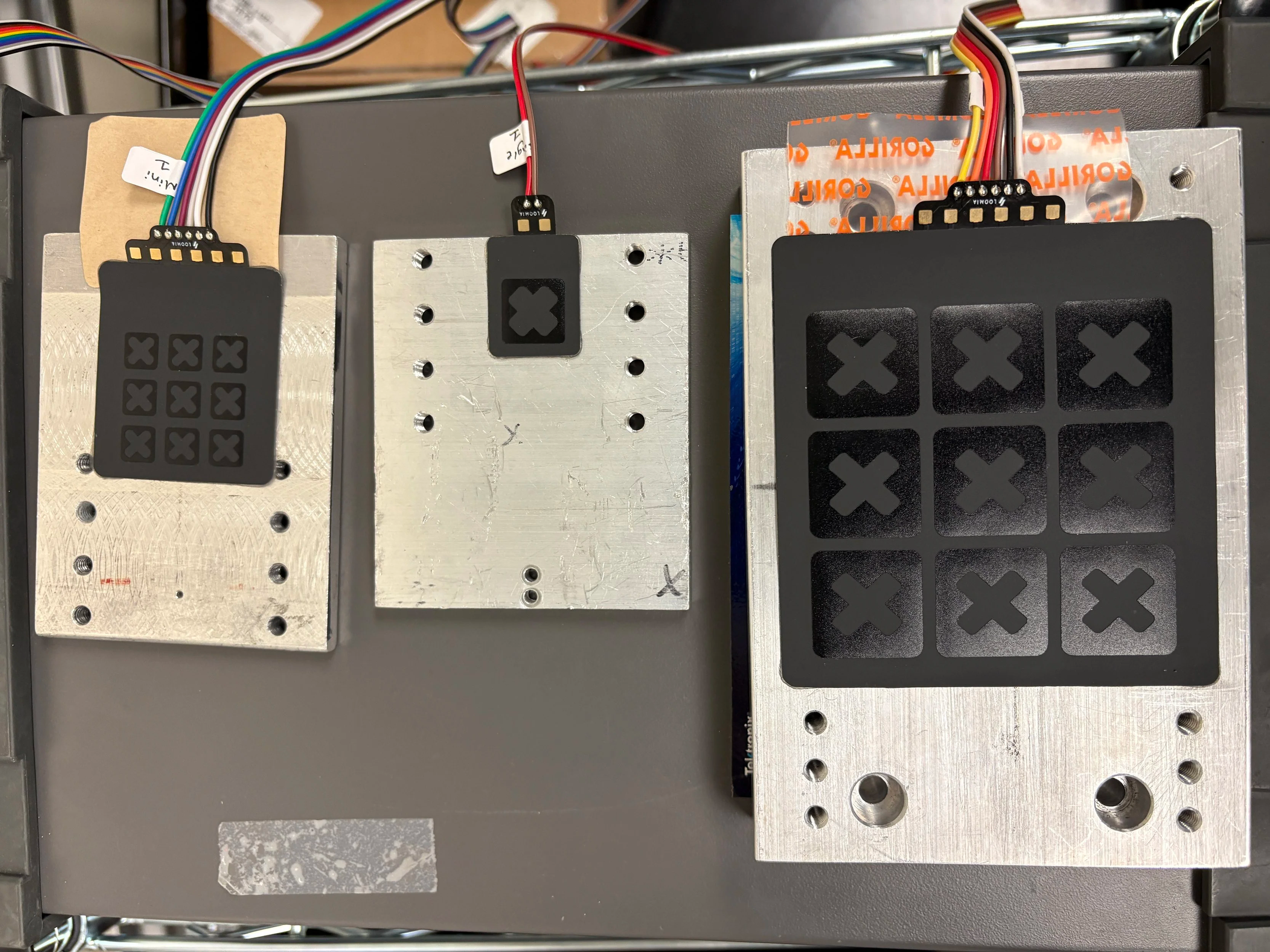

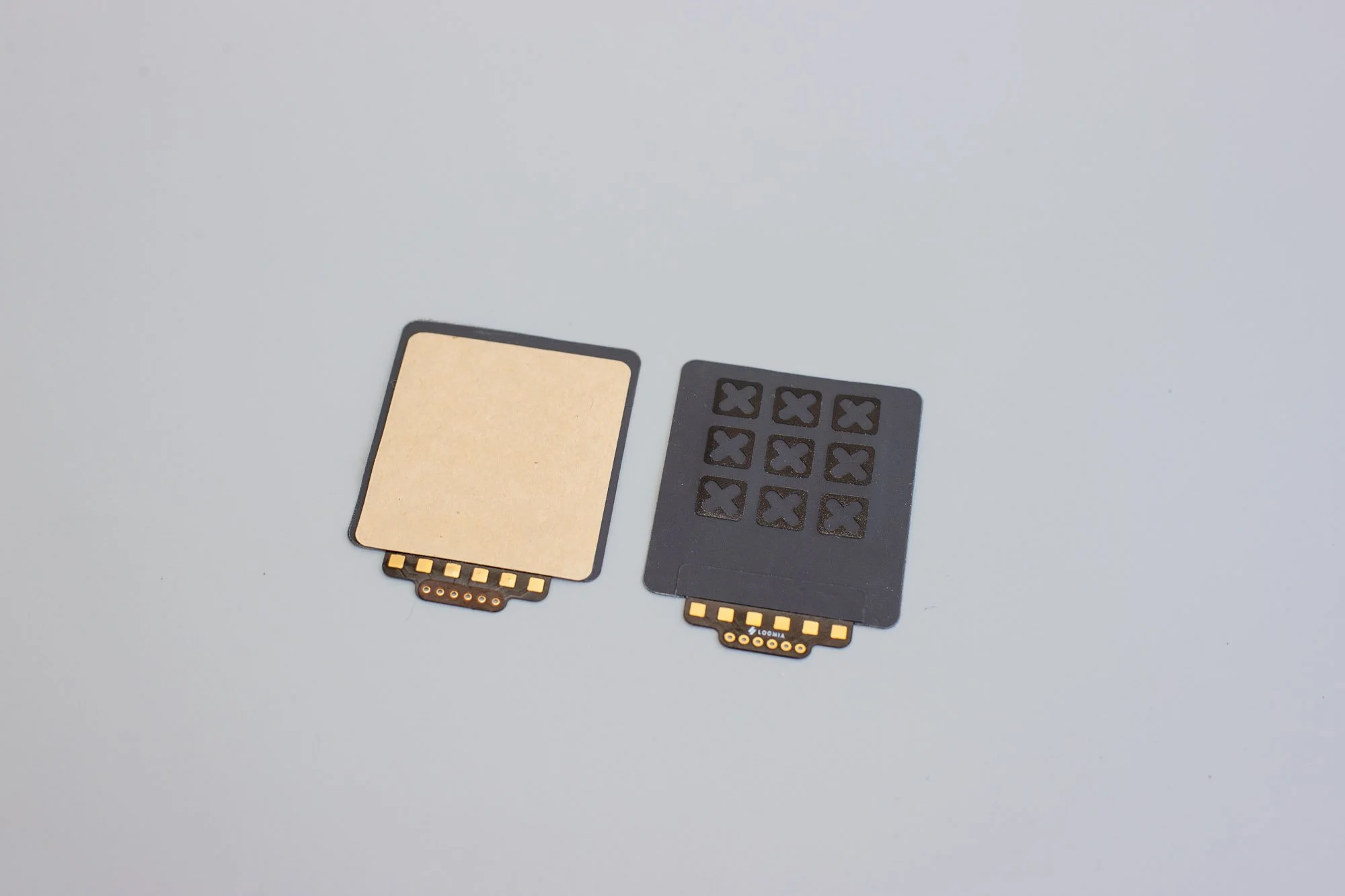

Test 1: For Mini and Mega FSRs

| Steps | Photos |

|---|---|

|

Arduino Setup

Open the Arduino app and connect the Arduino Uno board to your laptop.

Upload the sensor-reading code.

|

|

|

Attach Pogo Pin

Clip the pogo-pin to the Loomia Electronic Layer (LEL).

|

|

|

Connect to Breadboard

Connect the six-pin pogo-pin to the breadboard.

|

|

|

Resistor Wiring

Connect 680Ω resistors and jumper cables according to the wiring diagram.

|

|

|

Quadrant Verification

Open Serial Monitor and press each quadrant:

R1C1 → Quadrant 1

R1C2 → Quadrant 2

R1C3 → Quadrant 3

R2C1 → Quadrant 4

R2C2 → Quadrant 5

R2C3 → Quadrant 6

R3C1 → Quadrant 7

R3C2 → Quadrant 8

R3C3 → Quadrant 9

Confirm correct mapping.

|

|

|

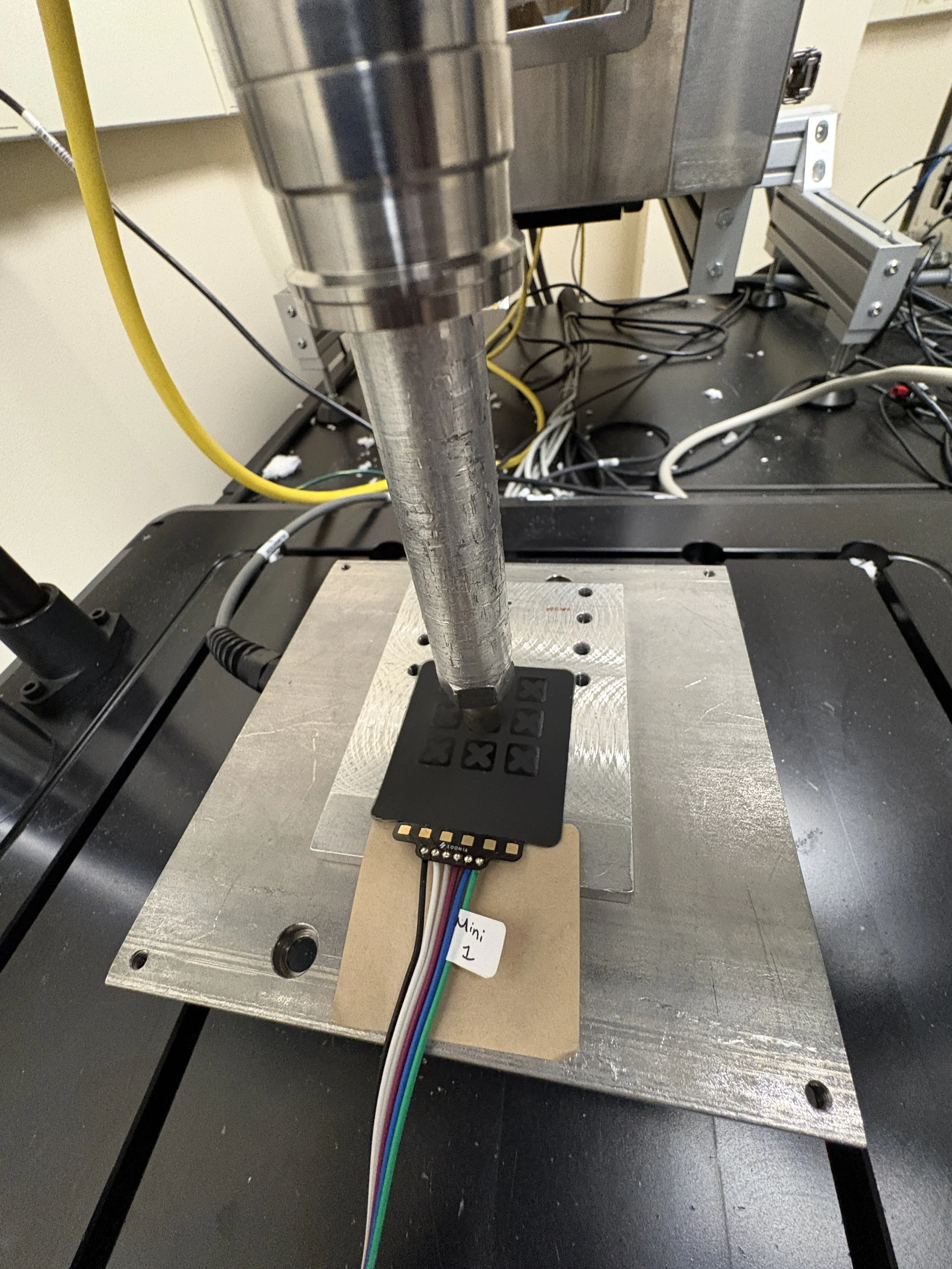

Sensor Placement

Place the sensor on a glass base after verification.

|

|

|

Testing Jig Placement

Place the designated testing jig on top of the sensor.

|

|

Test 2 Testing Steps

Copy the QC Template to a new spreadsheet to test the sensors.

Input the “Starting Range” before any weight is applied.

a) Most of the quadrants should be zeroed out with the Arduino set up. Although with the testing jig on top, there may be a few quadrants that jump between the 0-10 range, that's acceptable.

i) If any quadrants are above the 10 range, try to adjust the testing jig to see if it fixes the issue.

ii) If the issue persists even without a testing jig, there may be an issue with that sensor. Move it aside for further inspection.

To shorten our QC testing, we are only testing 30 grams and 500 grams on 3 diagonal quadrants: 1,5,9.

a) 30g= Weight bar, 10g, 10g

b) 500g= Weight bar, 10g, 10g, 20g, 50g, 100g, 100g, 100g, 100g

Place the 30g in quadrant 1, and record the range displayed.

Repeat Step 4 for quadrants 5 and 9.

Place the 500g in quadrant 1, and record the range displayed.

Repeat Step 6 for quadrants 5 and 9.

If the range is within the max and min range of the table below, then the sensor works as expected. If it is significantly above or below this range, move it aside for further inspection.

| Weight | Collective Mean | Min Range | Max Range |

|---|---|---|---|

| 30 g | 28.83333 | 17 | 43 |

| 500 g | 478.5 | 430 | 505 |

| Weight | Collective Mean | Min Range | Max Range |

|---|---|---|---|

| 30 g | 31.3333 | 10 | 51 |

| 500 g | 453.667 | 424 | 509 |