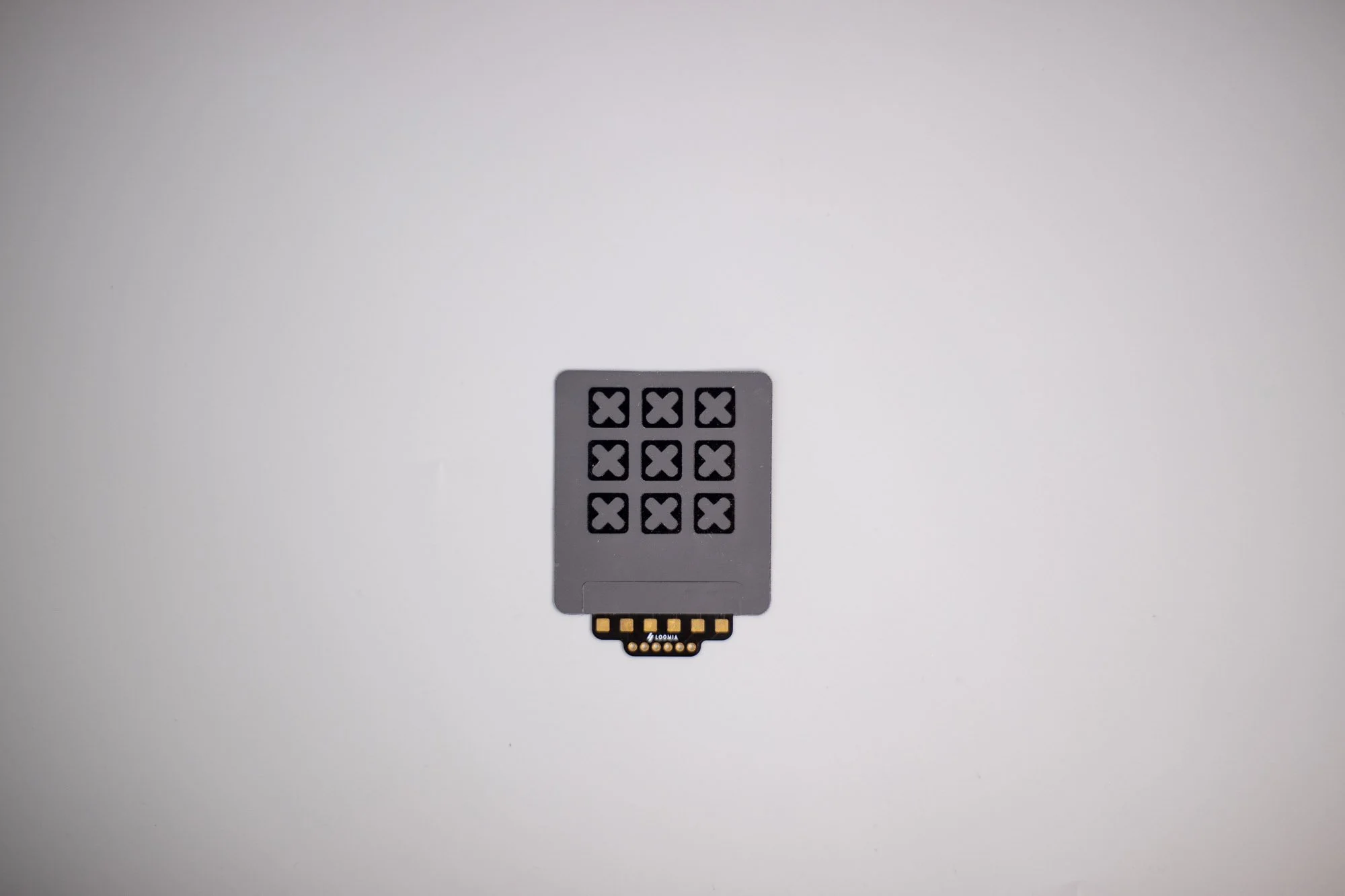

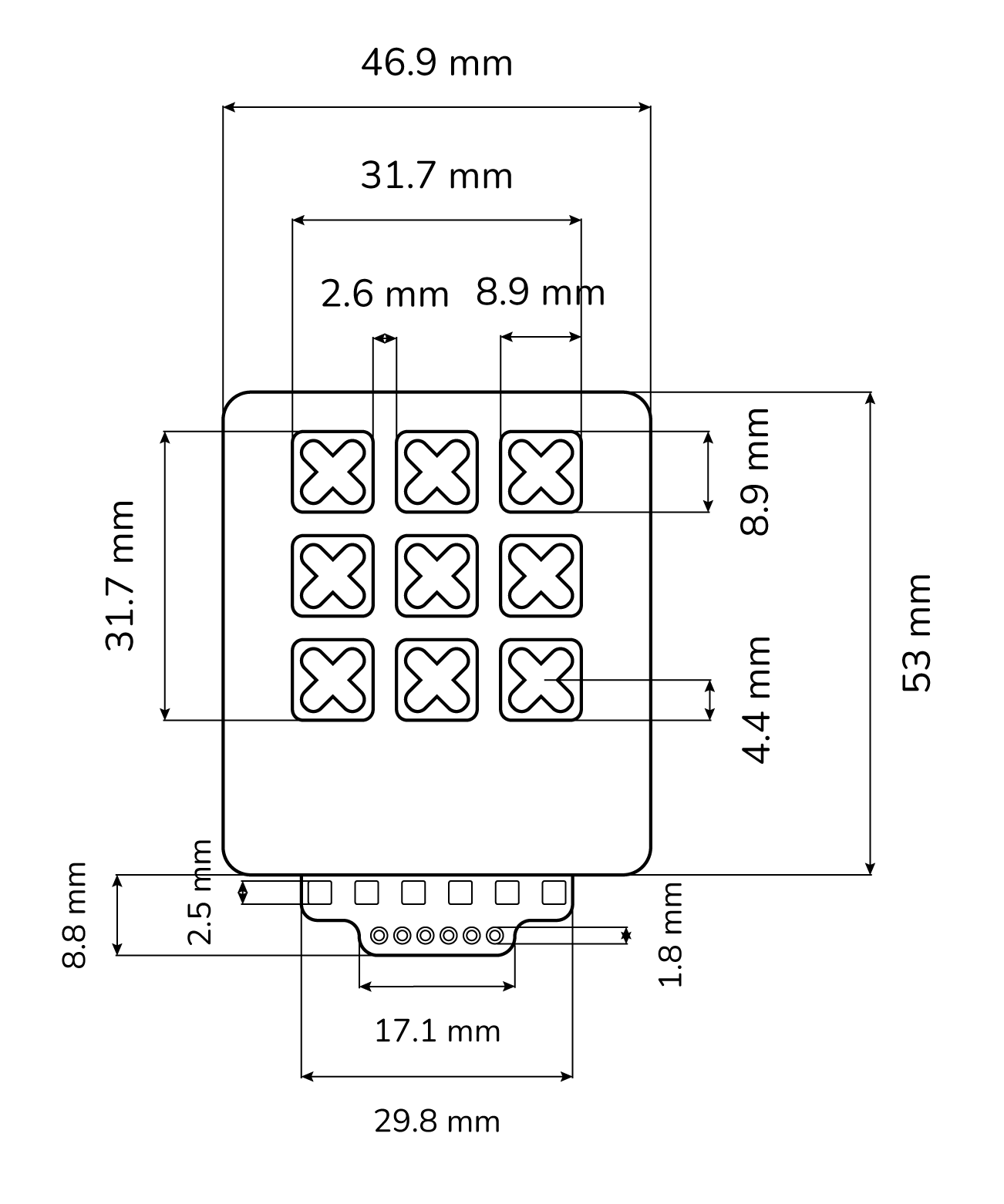

Loomia Force Sensitive Resistor (FSR) Features Overview

The table below provides data on standard Loomia FSR performance:

Resistive Sensor Specifications

Minimum Force

<0.5 N

Recommended Max Operational Force

65 N

Bend Radius

8 mm

Breaking Force

>100 N

Minimum Feature Size

2.5 mm

Thickness

0.5 mm

Drift

0.9% over 1 hour at 1 N

13.3% over 1 hour at 50 N

13.3% over 1 hour at 50 N

Durability

1,000,000+ cycles at 1 N

10,000+ cycles at 50 N

10,000+ cycles at 50 N

Hysteresis

Avg 5% per cycle (10 cycles at 1 N)

Avg 1% per cycle (10 cycles at 50 N)

Avg 1% per cycle (10 cycles at 50 N)

Software Support

Visualization

Arduino + Python Scripts

Arduino + Python Scripts

IP Rating

Internal tests show minimal ingress

Dataspeed

10 Hz

Performance Temperature Range

Coming Soon

Sensor to Sensor Variability

103%

Scalability

Up to 20,000 units per week

8-week lead time required

8-week lead time required

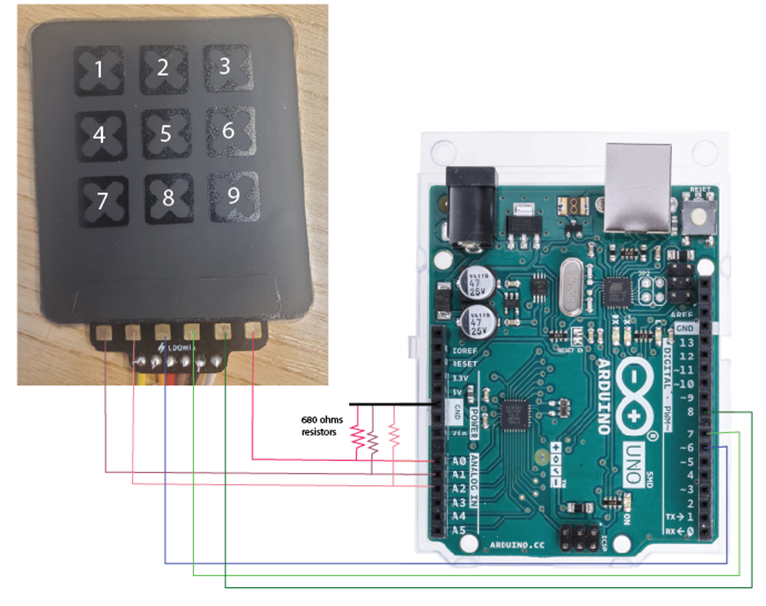

Arduino Code (serial monitor)

int colPins[3] = {6, 7, 8}; // Columns: GPIO outputs

int rowPins[3] = {A0, A1, A2}; // Rows: Analog inputs

const unsigned long samplingInterval = 100; // Sampling every 30 s

unsigned long lastSampleTime = 0;

unsigned long startTime;

void setup() {

Serial.begin(115200);

for (int i = 0; i < 3; i++) {

pinMode(colPins[i], OUTPUT);

digitalWrite(colPins[i], LOW);

}

startTime = millis();

lastSampleTime = 0;

// CSV Header

Serial.print("t");

for (int r = 1; r <= 3; r++) {

for (int c = 1; c <= 3; c++) {

Serial.print(",R");

Serial.print(r);

Serial.print("C");

Serial.print(c);

}

}

Serial.println();

// First sample at time = 0

logSample(0);

}

void loop() {

unsigned long currentTime = millis();

if (currentTime - startTime >= lastSampleTime + samplingInterval) {

lastSampleTime = currentTime - startTime;

logSample(lastSampleTime);

}

}

void logSample(unsigned long elapsedTime) {

Serial.print("t_");

Serial.print(elapsedTime);

for (int row = 0; row < 3; row++) {

for (int col = 0; col < 3; col++) {

digitalWrite(colPins[col], HIGH);

delayMicroseconds(50); // settle time

int val = analogRead(rowPins[row]);

digitalWrite(colPins[col], LOW);

Serial.print(",R");

Serial.print(row + 1);

Serial.print("C");

Serial.print(col + 1);

Serial.print("_");

Serial.print(val);

}

}

Serial.println();

}Arduino Pinout

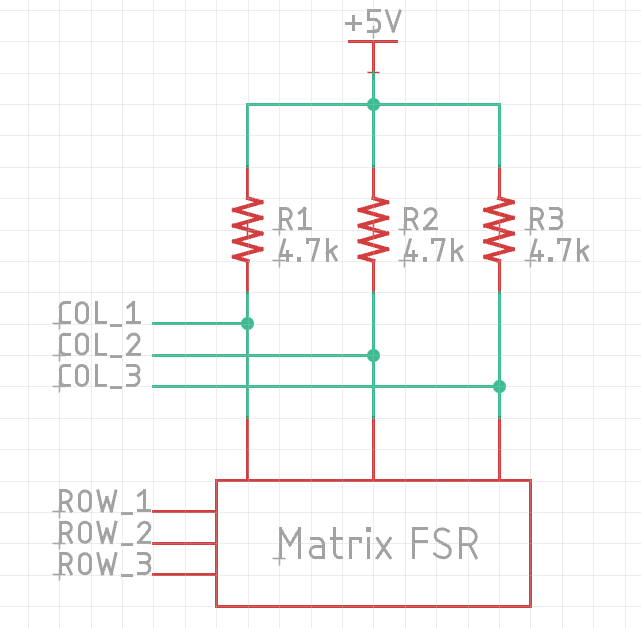

Arduino Code for Visualizer

/* Loomia - 3x3 Mini Pressure Matrix v1.0.2

Written for Loomia Technologies

By David Choi, Copyright 2025

Created: 6/17/2025

Modified: 11/24/2025

Description:

- For use with resistive matrices (3x3) with data output formatted for the Loomia Pressure Matrix Visualizer.

- Note: This code doesn't swap X-Y inputs for symmetrical outputs since touch point crosstalk is inherent to the resistive matrix design and no other electronics are used.

Hardware:

- Arduino Uno or compatible MCU with 10 bit ADC inputs

- Loomia 3x3 Pressure Matrix (V2 prototype)

- 4.7k external pull ups on column pins

Matrix Layout: X = Column; Y = Row; Origin = (1,1)

(Top: Pad Location)

Y3 |_ (1,3) _|_ (2,3) _|_ (3,3) _|

Y2 |_ (1,2) _|_ (2,2) _|_ (3,2) _|

Y1 |_ (1,1) _|_ (2,1) _|_ (3,1) _|

X1 X2 X3

Data Output Order: (1,1), (2,1), (3,1), (1,2), (2,2), (3,2), (1,3), (2,3), (3,3)

Data Output Format (all values uint16_t): val11,val21,val31,val12,val22,val32,val13,val23,val33\n

Change Log:

v1.0.2:

- High-Z for rows not being scanned. Improves intercell crosstalk somewhat.

- Add 4.7kΩ external pullups on columns

- Changed pins to match straight wiring fixture

*/

#define X1 A1

#define X2 A2

#define X3 A3

#define Y1 A0

#define Y2 A5

#define Y3 A4

const int16_t MAX_VALUE = 1023; // Due to 10 bit ADC

const uint8_t MAX_ROWS = 3;

const uint8_t MAX_COLS = 3;

uint8_t cols[MAX_COLS] = { X1, X2, X3 };

uint8_t rows[MAX_ROWS] = { Y1, Y2, Y3 };

uint16_t dataMatrix[MAX_ROWS][MAX_COLS] = {};

void setup() {

// Initialize pins

for (int i = 0; i < MAX_COLS; i++) {

pinMode(cols[i], INPUT); // Use external pull ups on columns (4.7k)

}

for (int i = 0; i < MAX_ROWS; i++) {

pinMode(rows[i], INPUT); // Set to high-Z

}

Serial.begin(9600);

}

void loop() {

readCells();

printData();

delay(50);

}

void readCells() {

// Read all column values for each row

for (int i = 0; i < MAX_ROWS; i++) {

pinMode(rows[i], OUTPUT);

digitalWrite(rows[i], LOW);

//delayMicroseconds(50); // Settling time

for (int j = 0; j < MAX_COLS; j++) {

dataMatrix[i][j] = MAX_VALUE - analogRead(cols[j]); // Invert value output for better viewing with visualizer

}

pinMode(rows[i], INPUT);

}

}

void printData() {

// Print all column data for each row

for (int i = 0; i < MAX_ROWS; i++) {

for (int j = 0; j < MAX_COLS; j++) {

Serial.print(dataMatrix[i][j]);

Serial.print((i == MAX_ROWS - 1 && j == MAX_COLS - 1) ? '\n' : ',');

}

}

}Visualizer Schematic

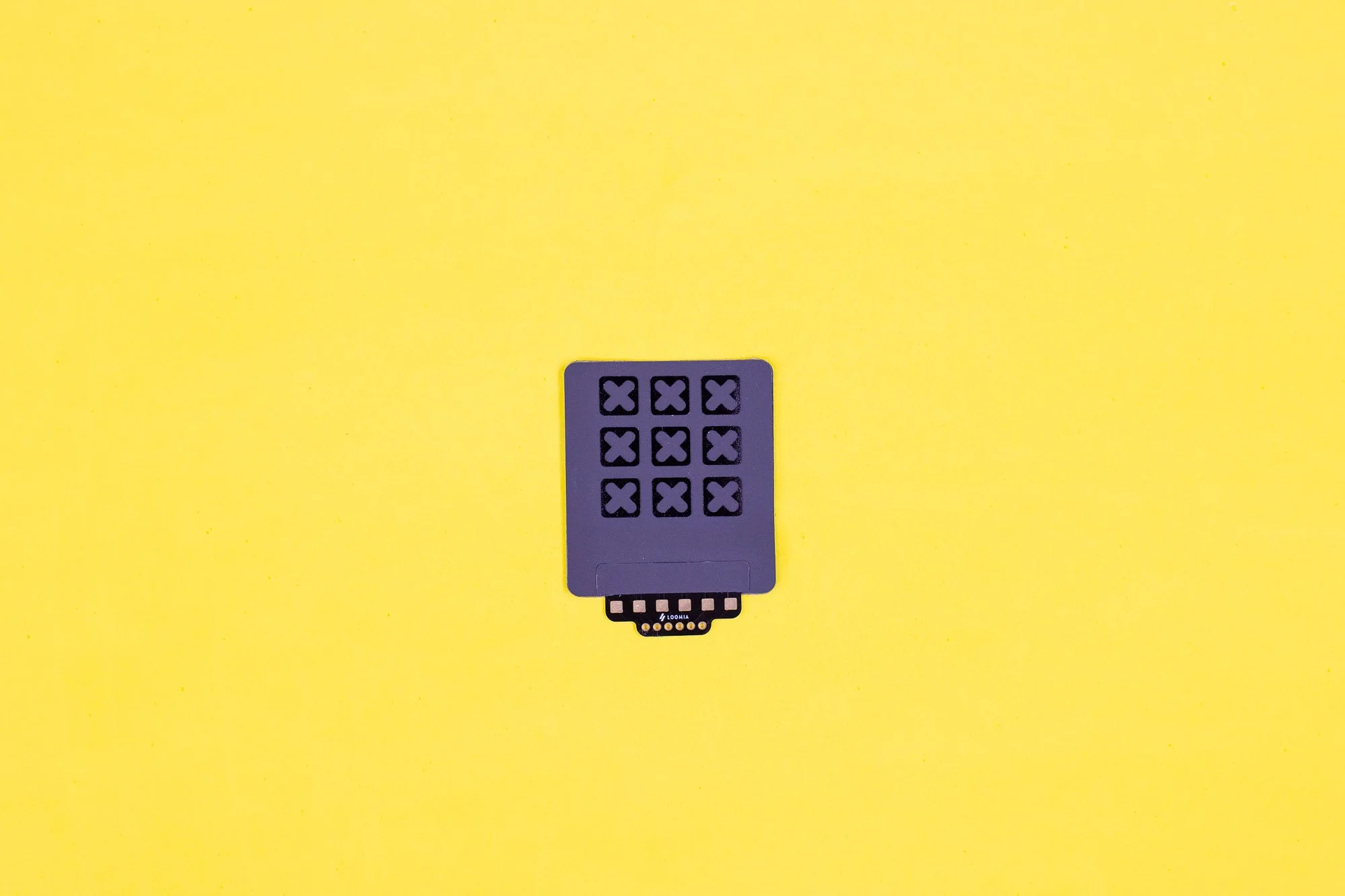

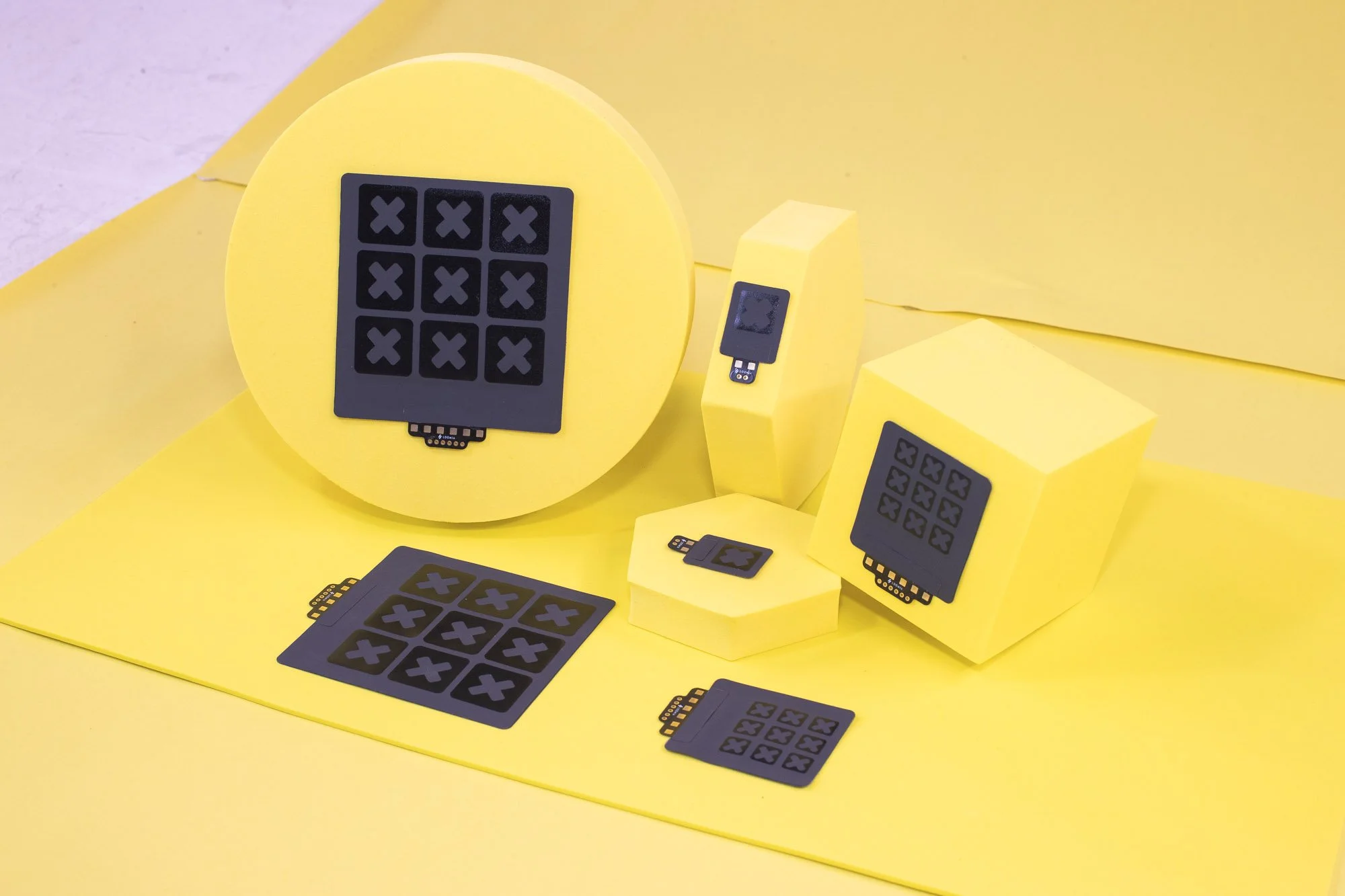

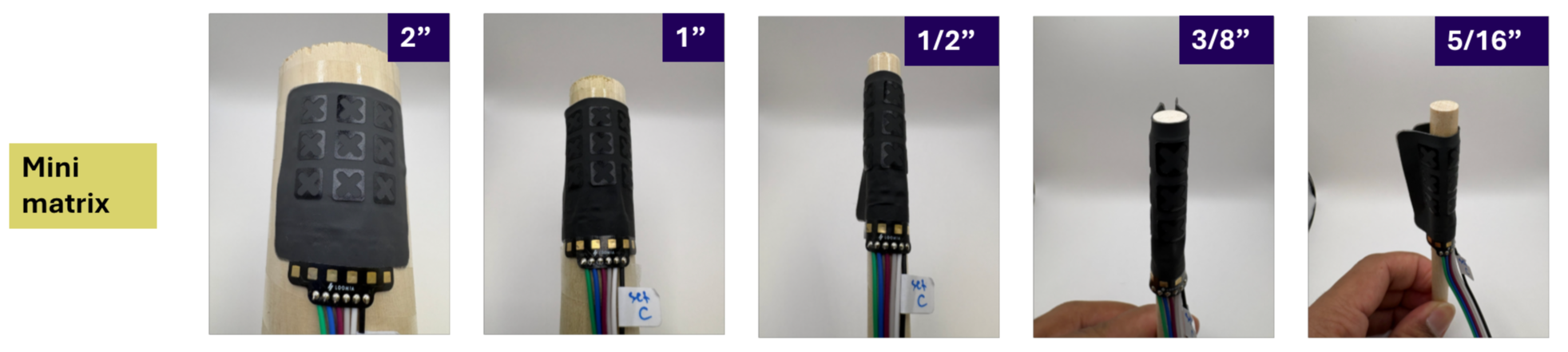

FSR Bend Radius and Integration

Validated Through Independent Lab Testing

Loomia FSRs have been evaluated in a university laboratory environment. The images above shown reflect bend radius testing.

Our sensors have a broad sensing range and reliable performance on both flat and gently curved surfaces.

Integration Instructions:

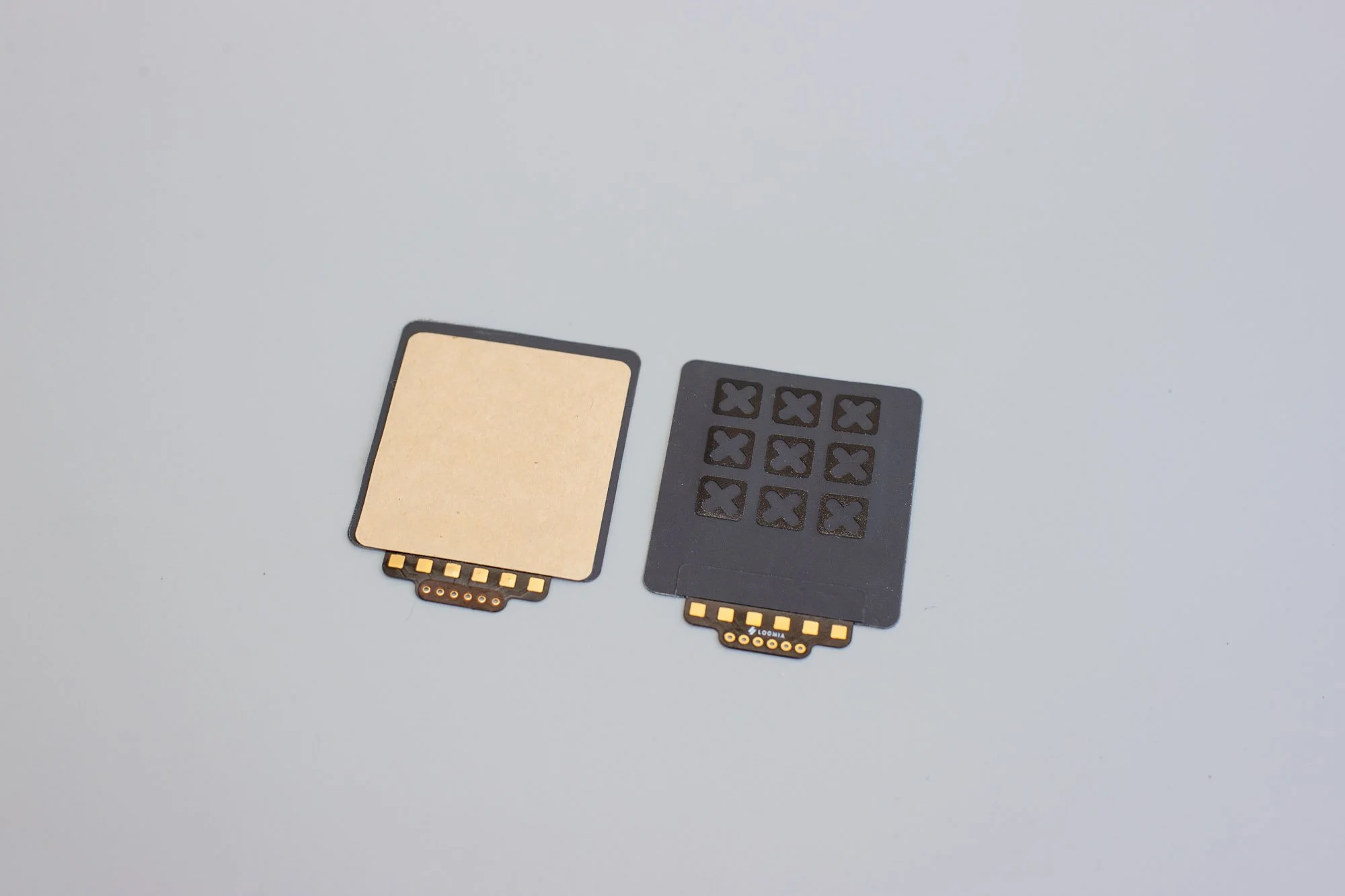

Our components are designed for easy integration onto surfaces. To attach our LEL to a surface (textile or plastic) Follow the instructions below:

Using the peel-and-stick backing, gently peel off the brown paper.

With adhesive exposed, apply the sticky component to your surface and ensure there are no bubbles.

Press down firmly

Do not lift or re-apply