Tactile Sensor Technologies Explained with Insights

More Questions? Our Tactile Sensing Specialist will Get in Touch.

What is a tactile sensor?

A tactile sensor is a device that measures specific properties of an object through physical contact between the sensor and the object. It functions like a system mimicking the human sense of touch, gathering information about characteristics such as temperature, shape, weight, texture, and pressure.

A tactile sensor is a versatile technology with applications across multiple industries. In robotics, it adds sensitivity to robotic hands, gloves, and grippers. In the automotive industry, a tactile sensor can create interactive surfaces that enhance comfort and user experience. It is also found in consumer electronics with touch screens, and in medical devices, such as prosthetic hands or arms, where a tactile sensor restores grip awareness and improves control.

Loomia’s tactile sensing technology is commonly used for applications in robotics, as its ultra-thin, flexible, and easy-to-integrate tactile sensor gives robots the power to feel their surroundings. As we know today, generative AI is evolving from bits to atoms, and more humanoid robots are being developed to make AI act in the physical world. While the robots’ “brain” processes commands, it is the body, specifically the surfaces, that enables it to feel, respond, and interact with the environment. Hands and fingers alone account for more than 17% of the robot, the biggest percentage of spending on a humanoid. Making these sensor-rich areas work properly is an essential part of Embodied AI interaction in the world. This is where tactile sensor technologies like Loomia’s have emerged to provide this missing sense of touch and made physical interaction far more natural and precise. The next section of this article will go through current tactile sensor technologies that have become widely adopted in today’s market to be integrated into robots, robotic hands, and grippers.

Source: IDTechEx

Tactile Sensor Technologies Most Frequently Used in Today’s Market

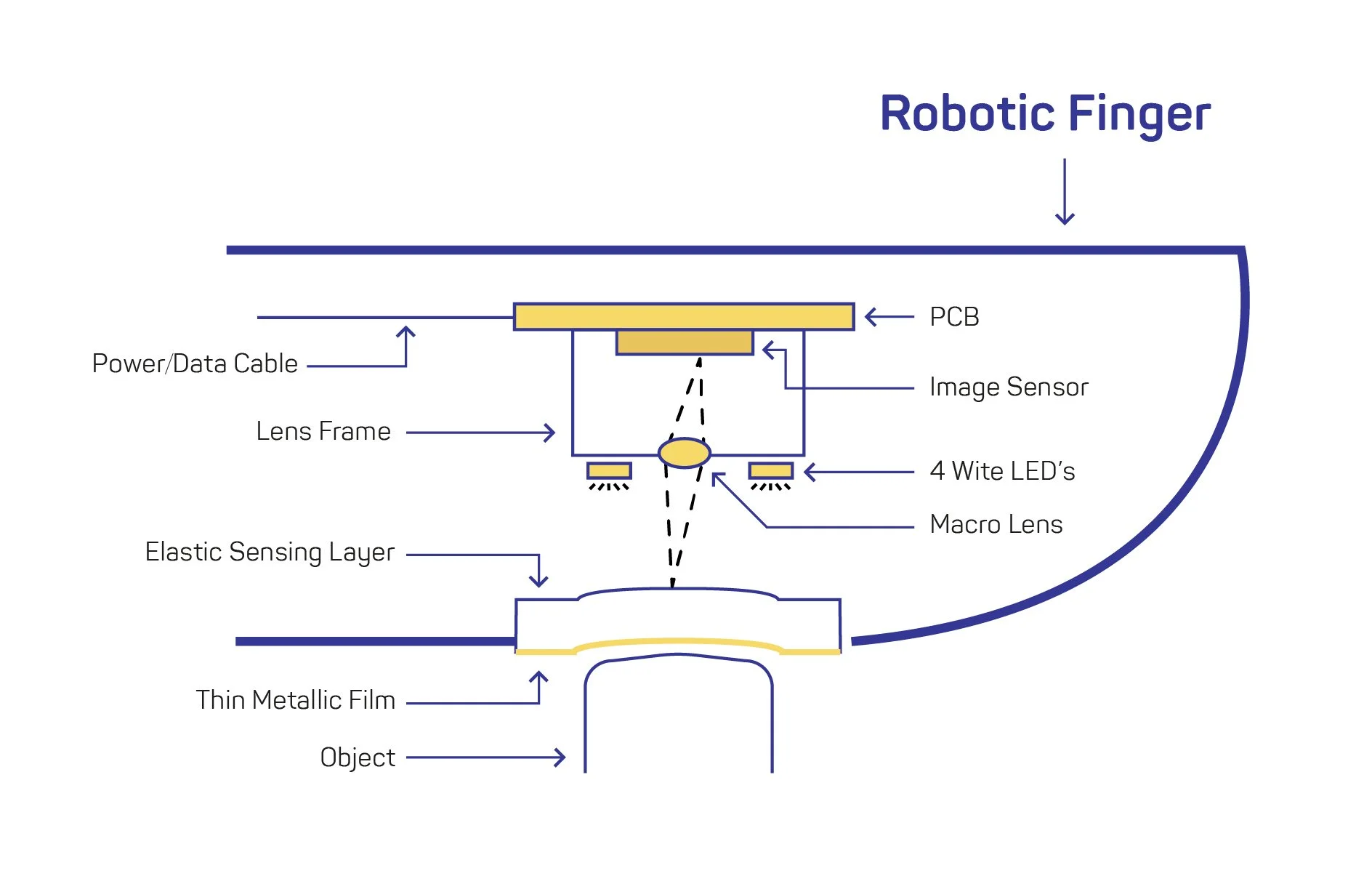

1) Optical Tactile Sensor Technology

An optical tactile sensor uses vision-based methods to capture and interpret touch. Instead of relying on electrical signals alone, this tactile sensor integrates a camera, a light source, and a soft silicone surface layer. When force is applied to the cap, it deforms, altering the light patterns inside. The camera captures these changes and translates them into tactile information, which allows the system to detect contact, pressure, and even the direction of applied forces.

Advantages:

The main strength of an optical tactile sensor is its high resolution and data richness. It provides detailed feedback with many data points and enables the detection of complex inputs such as shear or angled forces.

Because many robotics teams already use cameras for navigation, integrating an optical tactile sensor into robotic hands or grippers can align well with existing processing systems.

Optical sensors are also relatively durable compared to some other tactile sensor types.

Limitations:

It is often expensive, bulky, and limited in placement. They are only compatible with specific hands that they were designed for.

Optical tactile sensors also struggle to detect very light touches, and their size makes them impractical for human-worn applications, such as gloves for data collection or algorithm training.

Market adoption: Several companies are advancing optical tactile sensor technology, including GelSight (GelSight 360), FingerVision, and Shadow Robot.

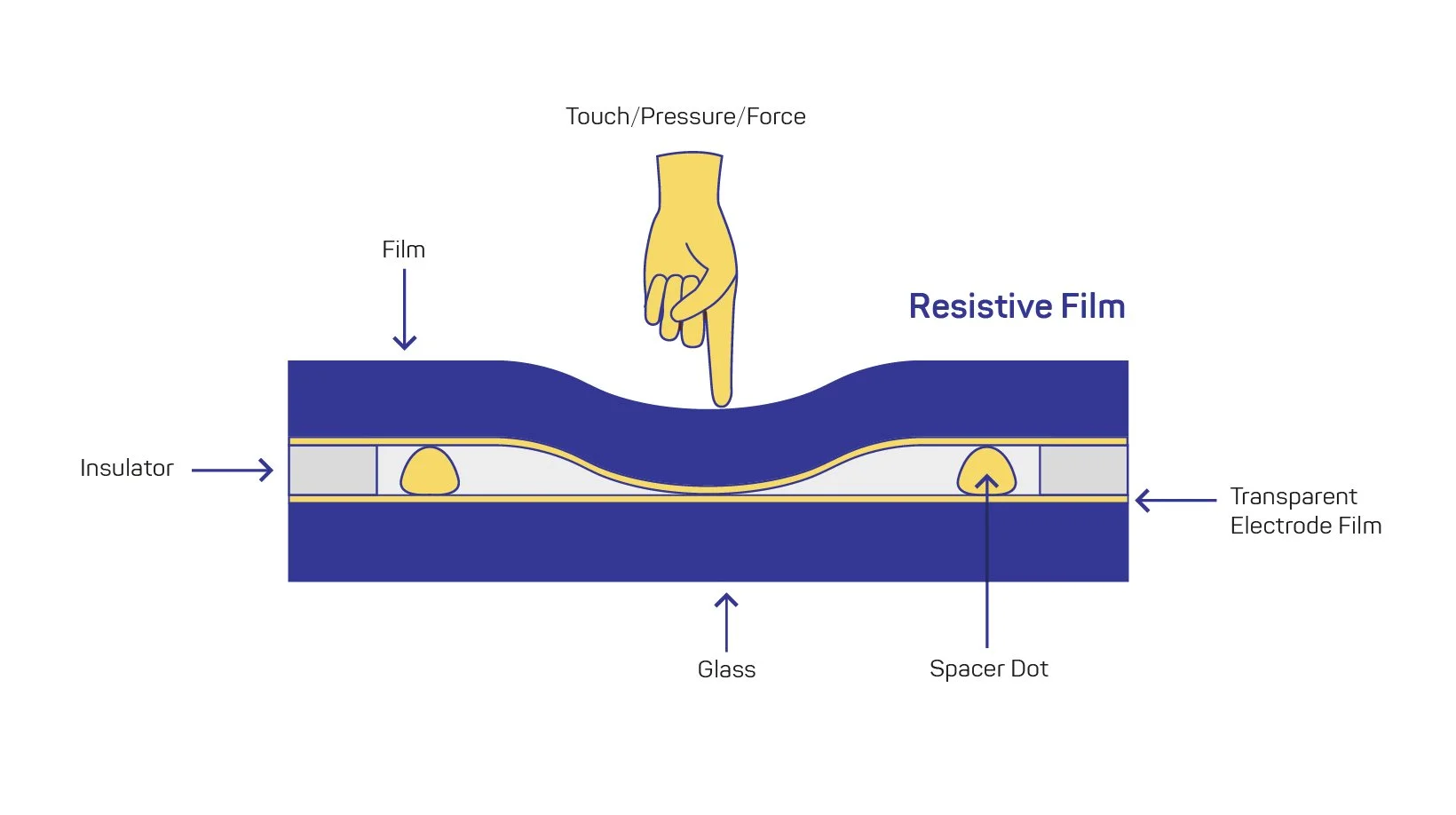

2) Piezoresistive Tactile Sensor Technology

A piezoresistive tactile sensor is one of the most established and straightforward approaches to touch sensing. This technology relies on layering conductive and non-conductive materials. When force is applied, the pressure changes the material’s resistance or voltage, and this variation is measured to detect the presence and magnitude of touch.

Advantages:

The biggest strength of a piezoresistive tactile sensor is its simplicity and cost-effectiveness.

Because the design can be manufactured in a variety of shapes and sizes, integration is highly flexible. These sensors are also less bulky than optical systems, which makes them ideal for compact applications.

Importantly, they can be embedded into tactile gloves for humans, providing valuable data for machine learning and robotic training.

Limitations:

They are generally restricted to normal force detection (straight-down pressure). Detecting shear forces, such as sliding or angled touches, is still an area of ongoing development and research, including efforts by Loomia and other teams.

Market adoption. Companies working with this approach include Loomia, Touchlab, and Brighter Signals.

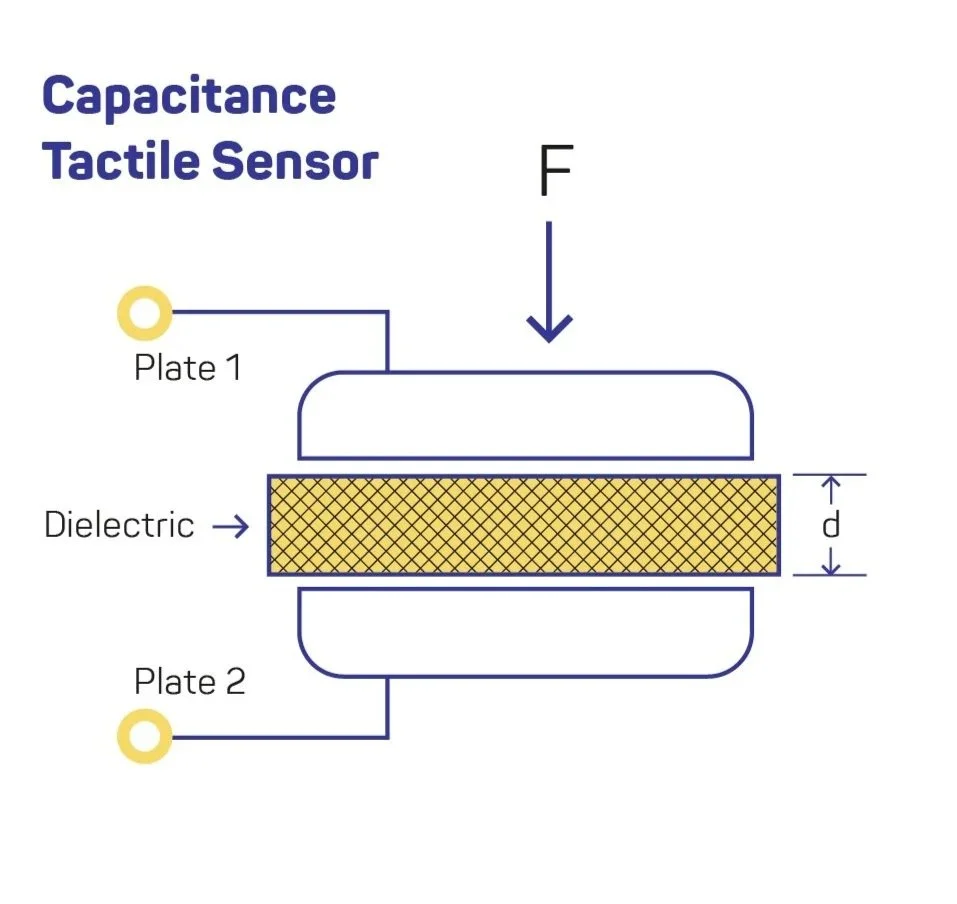

3) Capacitive Tactile Sensor Technology

A capacitive tactile sensor works on a principle similar to piezoresistive sensing but relies on changes in capacitance rather than resistance. When force is applied, the distance or alignment between conductive layers shifts, which alters the sensor’s capacitance. This change is measured and interpreted as touch or pressure.

Advantages:

One of the main strengths of a capacitive tactile sensor is its sensitivity to a wide range of conductive materials, including metals and human skin. This property makes it highly effective in applications like touchscreens and consumer electronics, where detecting even light finger contact is crucial.

Like piezoresistive sensors, capacitive designs can be adapted into different forms, giving engineers flexibility in integration.

Limitations: The same sensitivity that makes this tactile sensor useful can also be a drawback. Capacitive sensors are more easily influenced by environmental interference, such as vibration. This can sometimes lead to signal noise or unintended activation.

Market adoption: Capacitive tactile sensor technology is widely used in consumer devices, most notably in touchscreen technology.

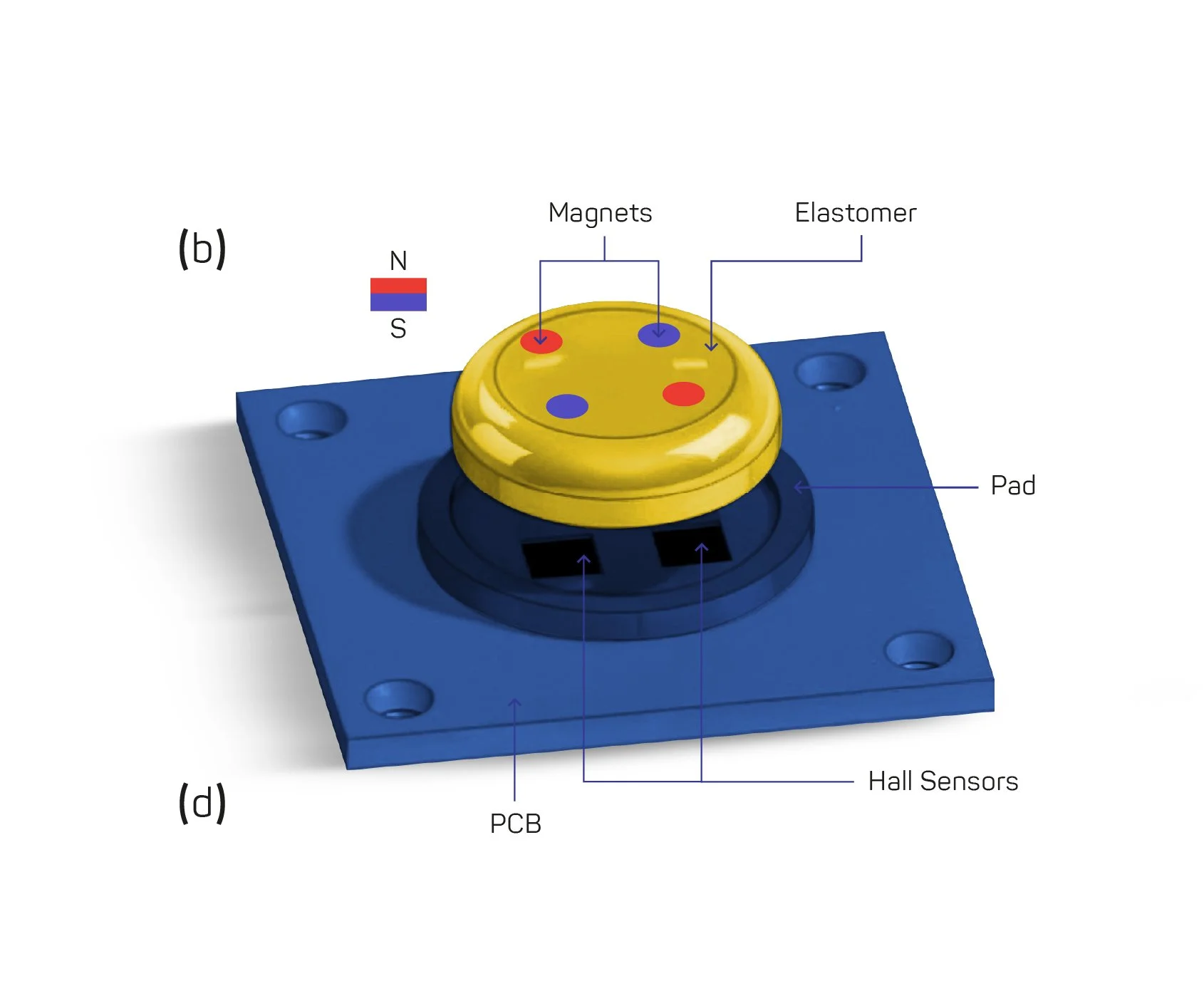

4) Hall-Effect Tactile Sensor Technology

A Hall-effect tactile sensor detects touch by measuring changes in a magnetic field when force is applied. This design often involves placing a magnet and a sensing element in close proximity. When a tactile force shifts the magnet’s position, the magnetic field changes, and the sensor interprets this variation as touch input.

Advantages: Compared to piezoresistive or piezocapacitive approaches, a Hall-effect tactile sensor is better at detecting shear forces.

Limitations. Hall-effect sensors are generally bulkier than other tactile sensor technologies, which can restrict integration into compact systems. They are also susceptible to interference from nearby conductive or magnetic materials, which may affect performance.

What Distinguishes a Tactile Sensor by Loomia

A tactile sensor by Loomia can be built with either capacitive or resistive sensing, depending on the application. At just 0.5 mm thick, it is highly flexible and designed to conform to complex shapes, making it suitable for fingers, knuckles, gloves, and other curved surfaces. With a peel-and-stick option, integration into products is simple and fast.

At scale, a Loomia tactile sensor is also cost-effective, priced at under $100 per unit (at 1,000 units). Production is ISO 9001-certified with the capacity to manufacture up to 20,000 units per week, ensuring both quality and scalability.

Loomia is also developing methods of integrating shear force sensing into our flat and flexible sensors for contact and shear force applications.